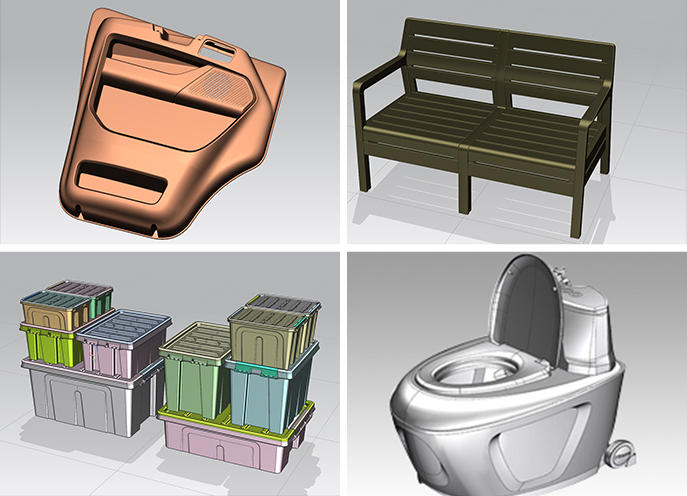

R & D MOULD engineers use modern technology design tools and technological software from world leading manufacturers, such as CAD, CAE, CAM, each of which makes it possible to carry out:

- Product sample;

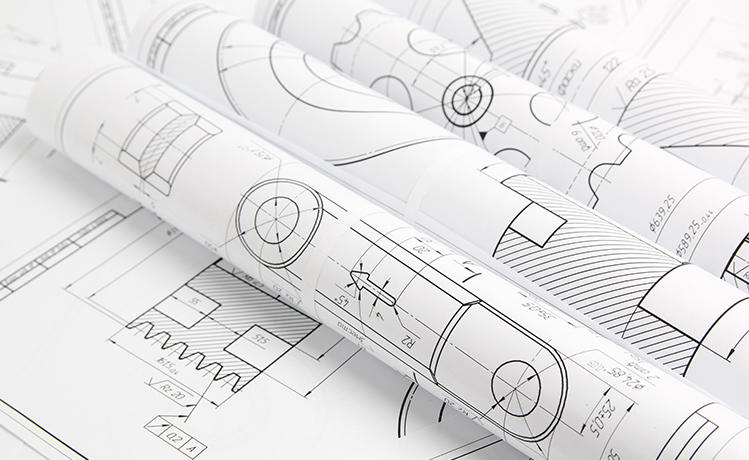

- 2D drawings in electronic form (possible formats DWG; DXF, SLDDRW), or on paper carrier;

- 3D models in STEP, Parasolid, IGES or others format.

After obtaining product information, engineers proceed with the following steps:

- If there is a sample of the product, 3D-scanned, point clouds and building a 3D model of the product;

- In the presence of 2D drawings, the task is simplified and comes down to building a 3D model according to drawing.

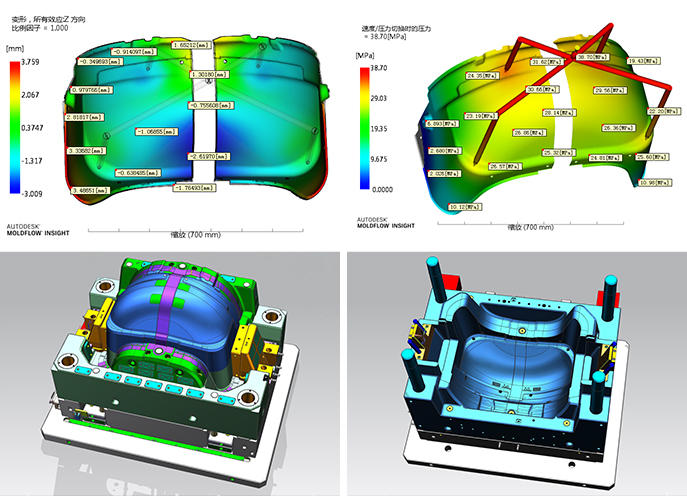

In the mean time of develop the mold design, Designers carry out a computer analysis of the following parameters:

- checking the adequacy of the angles on surfaces of the 3D model, especially on textured and embossed surfaces;

- checking the permissible wall thickness of the product;

- determination of the sprue type, injection points and analysis of product spillage;

- determination of the mold cooling scheme and analysis of its efficiency;

- determination of possible places of accumulation of air in the cavities of the forming parts (FOD) and ensuring its release.

- analysis of filling with plastic

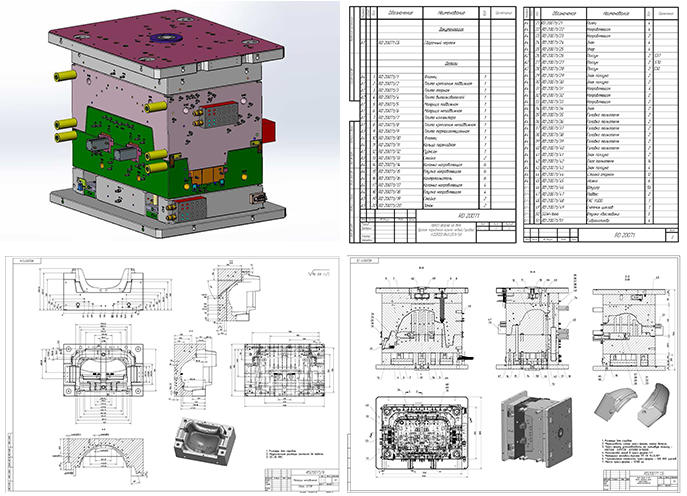

Together with the mold, we are ready to provide the following document:

- Mould assembly drawing

- Control schemes:electrical control circuit, hydraulic control circuit, pneumatic control circuit, kinematic control circuit, cooling system diagram and pressure test results, hot runner diagram (with catalog numbers)

- certificates for steel used in the manufacture

- hardness chart for original tooling parts

- the result of calculating "Мold Flow"