+86-576-84352333

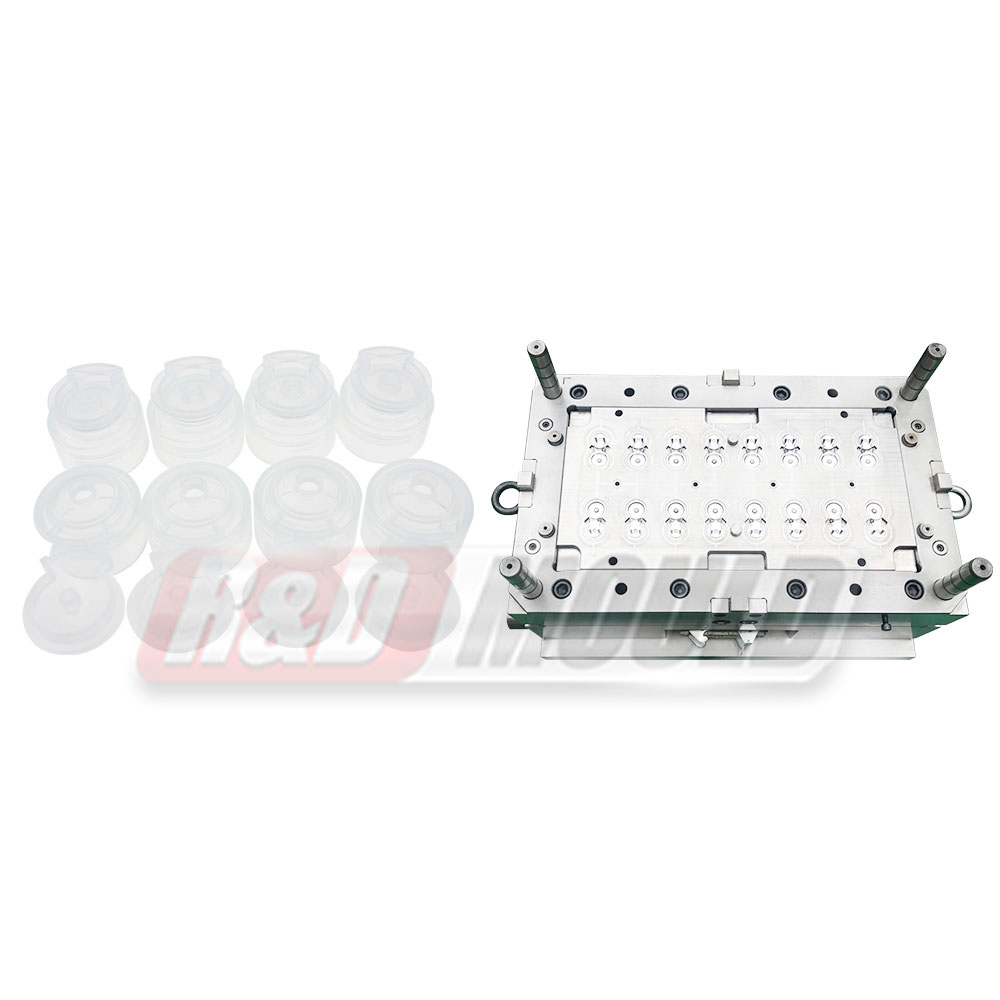

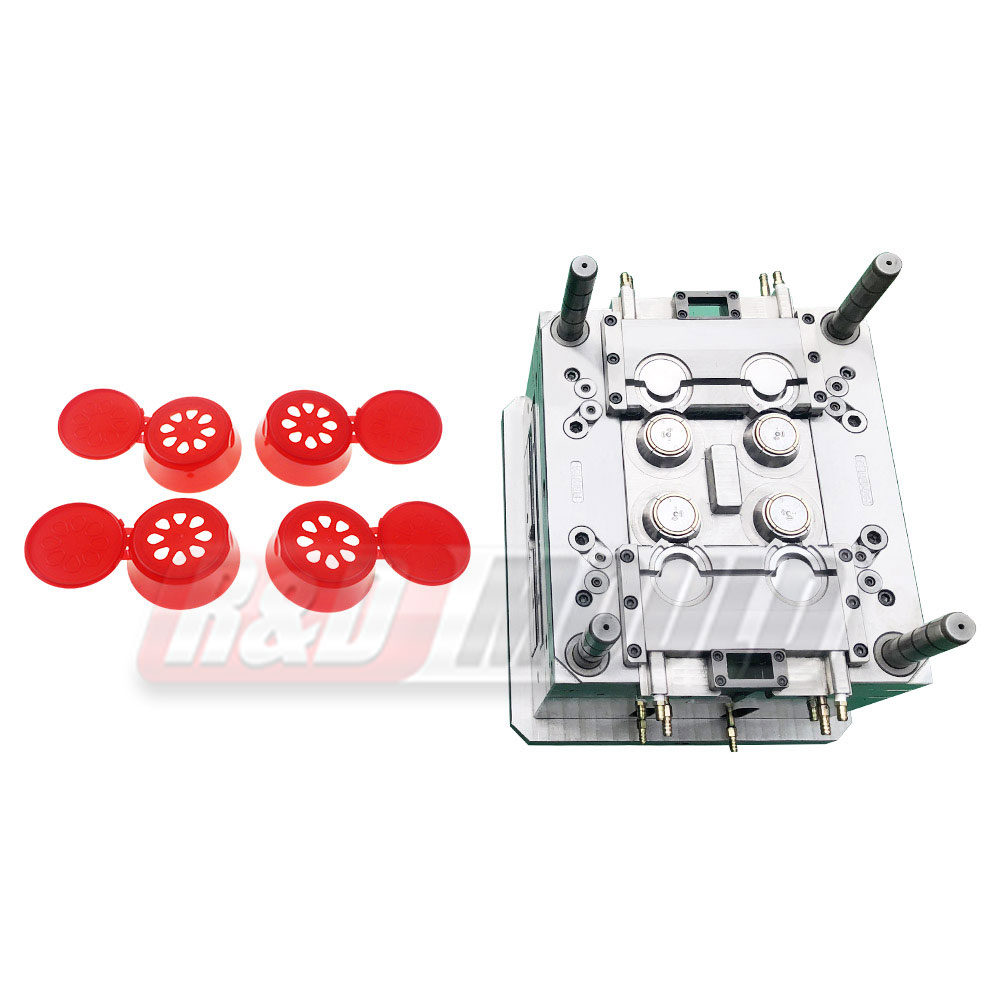

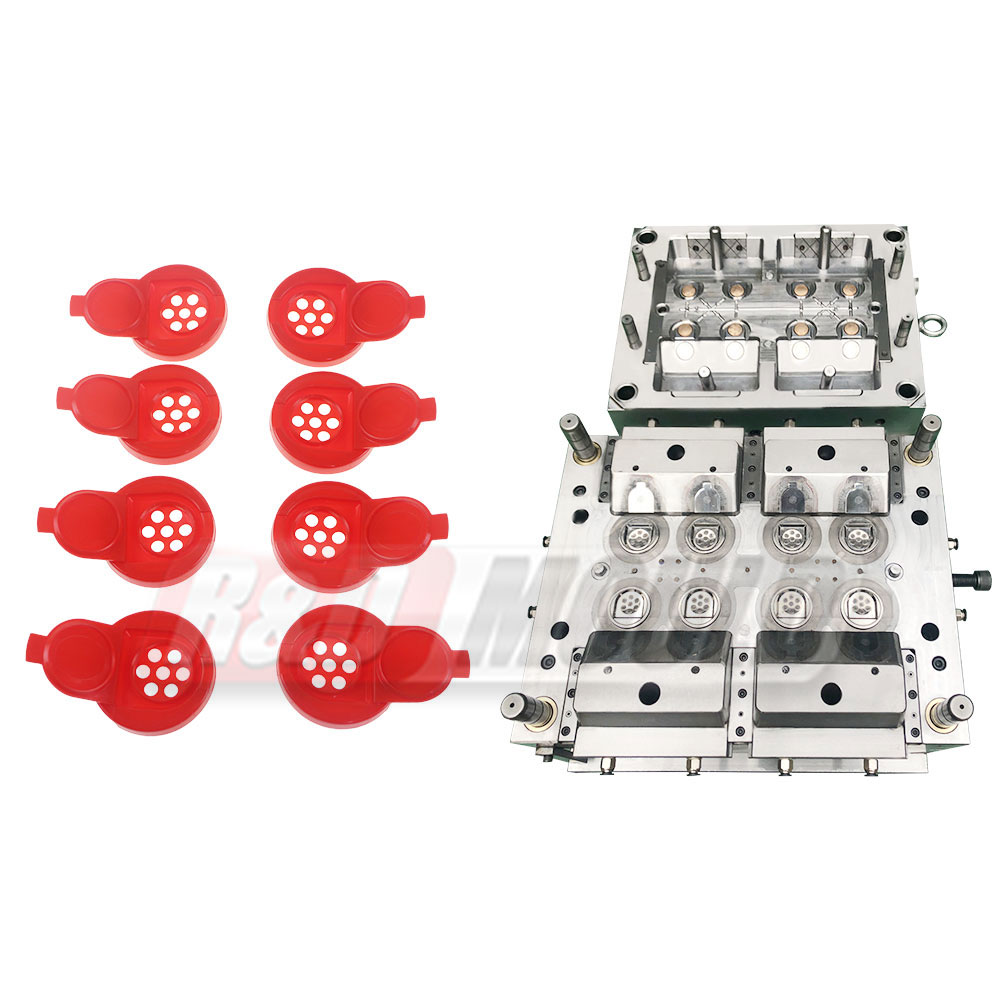

We Produce beverage cap closures mould on injection moulding technology, for applications within the dairy and fruit juice industries for both HDPE & PET bottles and 3 or 5 gallon cap mould, flip top cap mould, inner cap mould and screw cap mould etc .

The cap moulds have won high praise from our customers because of superior mould quality, high precision, long mould life, short deliver time, fast cycle time and reasonable price features.

For the cap mould, we want to share some technique points:

-Adopt advanced CNC machine, EDM machine, high speed engraving machine to make sure tight tolerance;

-Use high grade steel S136, 2316, H13 to guarantee 5million mould life and good quality;

-Optional water cooling system for fast cycle time;

-Stable Performance hot runner and temperature controller;

-Self-lock in order to avoid eccentric of the mould;

-Interchangeable core insert, it is better for future maintenance when assembly;

-Multi-cavity for mass production;

-All cap moulds are automatically eject.

If you have new projects of cap moulds, please send us details. We can suggest the cavity number and select mould steel for you according to your injection machine , your expected mould life and your requirements. Hope we can start business from this project.

English

English عربى

عربى Español

Español Français

Français