+86-576-84352333

Molds for containers and packaging including Paint Buckets Mould, containers mould of various capacities and shapes. Thin-wall container mould , IML Mold, Preforms Mould for PET bottles. Cap Closure Mould, Cutlery Mould

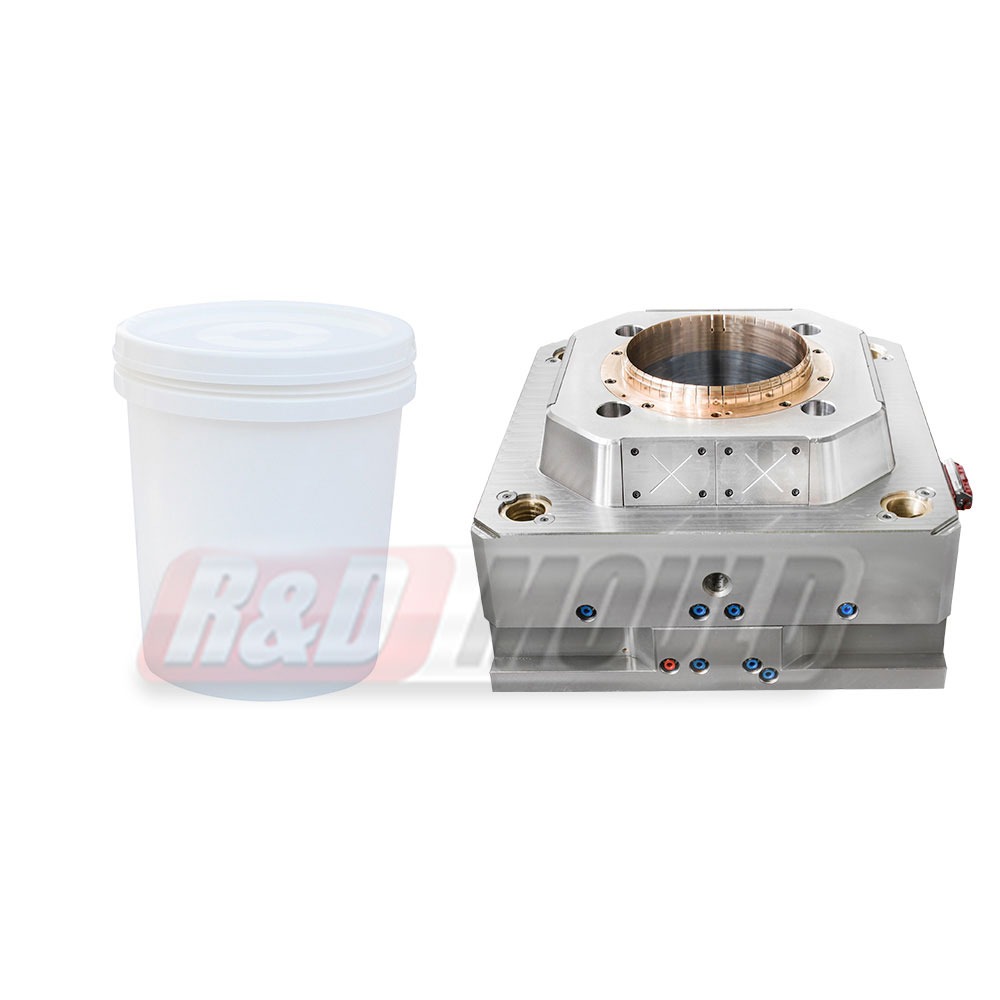

R&D Mould is professional Paint Pail Bucket Mould manufacturers and factory in China. We produce Paint bucket Mould from 0.5L-22L, During the past 10 years,we made so many bucket moulds for our customer and conclude some technical points to share with you in paint pail mould designing and manufacturing as below

1.Professional bucket mould design is the principal of good bucket mould.

Especially for cooling system design ,in our company, we have the cooling system designed in the core ,slider,stripper,cavity.

For paint bucket mould core, design the cooling channel 15mm below the molding surface.And the diameter of the paint bucket mould cooling channel should be more than 12mm, so that the water can run smoothly in the channel while taking away the heat in the core.

For paint bucket mould cavity,the cooling system design near the hot runner tip area is very important, this area is very sensitivity. Bad cooling system will directly influence the bucket's cycle time and out looking.

2.Good and suitable steel selection for bucket mould is very important.

To make a high quality painting bucket mould, we have to choose suitable steel for the bucket mould.

Normally ,for a paint bucket mould life is 1 million, we suggest to choose 2738 for the cavity and core steel ,with HRC35-38.

For a paint bucket mould life require over 3 million, we suggest to choose 2344 for the cavity and core steel ,with HRC45-48.

Of course ,some customer want to reach high speed injection with shorter cycle time, we suggest to use BeCu insert in the core top,cavity bottom and slider.

3.Precision tooling guarantee even injection and material flow.

The painting bucket moulds core eccentric causing the pail wall thickness not even and the pail out of center.This problem is very common, but virulent for the mould life.

So good and precision machining process select is very important.

English

English عربى

عربى Español

Español Français

Français