As a molds manufacturer specializing in SMC molds, we understand the challenges that come with the process of demolding. The question on everyone's mind is, "How to Achieve Smooth Demolding in SMC Processes?" Let's dive into the user's pain points and provide some clear, actionable answers.

1. Material Waste

One of the concerns of mold manufacturers is to reduce material waste. How can we reduce waste in the molding process? is a common query. The advantage of it is that it eliminates the need for a gating system, which traditionally leads to material loss. By using it, manufacturers can ensure that less raw material is wasted, as the material is directly placed into the mold, reducing the amount of scrap generated during the molding process. This not only cuts costs but also aligns with sustainability goals.

2. Uniform Pressure and Deformation

Another pain point is achieving uniform pressure within the mold to prevent deformation. Users often ask, How do molds ensure even pressure distribution? The design of SMC molds allows for more even pressure distribution throughout the mold, which is critical to maintaining product integrity. The pressure, which means less deformation and lower internal stress in the finished SMC product. This is particularly important for manufacturers looking to produce parts with precise dimensions and high structural integrity.

3. Demolding of Thin-Walled and Large Products

Manufacturers often struggle with the demolding of thin-walled and large products. The question arises, "How can SMC molds handle the demolding of complex shapes?" They are particularly adept at forming thin-walled products without warping, thanks to the low internal stress created during the molding process. Additionally, the multi-directional flow of plastic in the mold cavity allows for the formation of larger, flat, or basin-shaped products that might be challenging with other molding methods.

User Needs and Solutions

Users need solutions that are not only efficient but also reliable. They ask, "How can we trust the quality of SMC molds?" The answer lies in the precision engineering and materials science that goes into the creation of each of our molds. By ensuring that the and that the is also placed under high pressure, manufacturers can achieve a high level of consistency and quality in their SMC products.

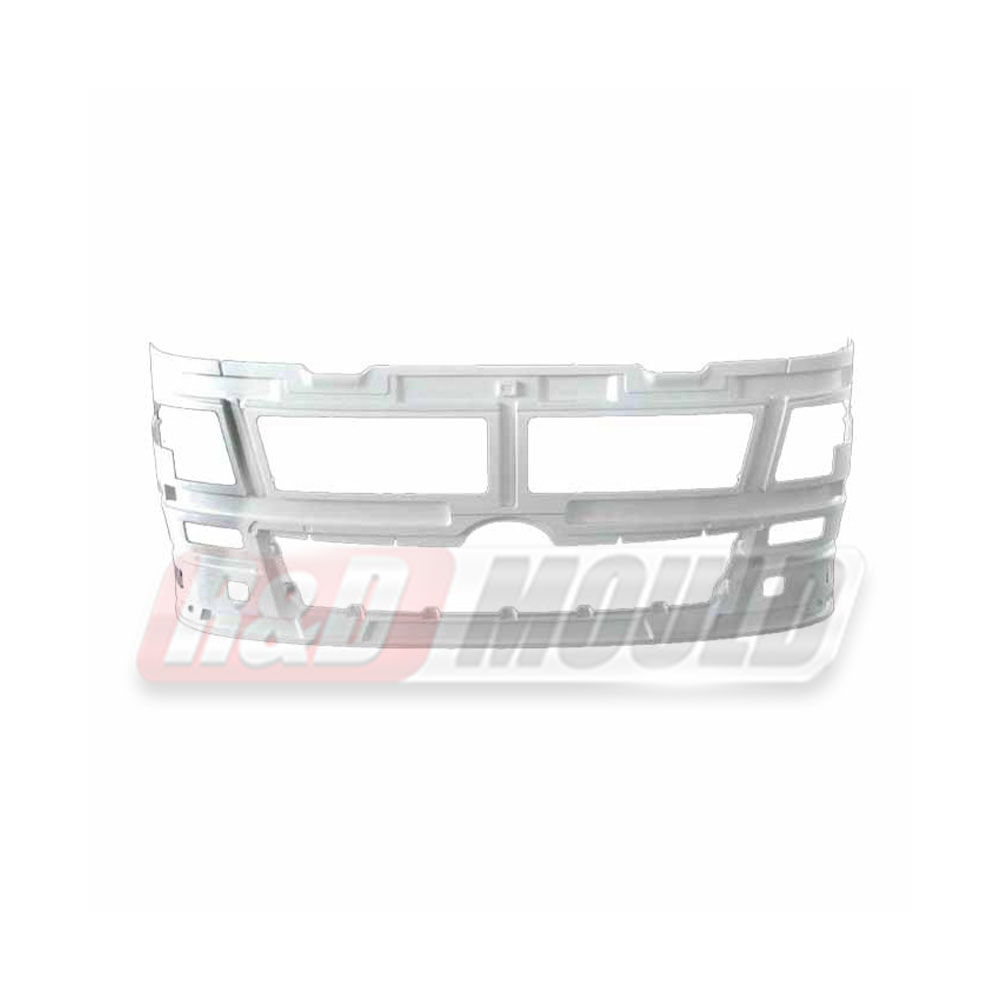

.jpg)

Users are interested in the longevity of their molds. They wonder, "How long will mold last?" The absence of a gating system and the even distribution of pressure mean that SMC molds experience less wear and tear, extending their lifespan compared to traditional molds. This durability is a significant selling point for mold manufacturers looking to offer a long-term solution to their clients.

SMC molds offer a range of advantages that cater to the needs of manufacturers. By reducing material waste, ensuring even pressure distribution, and easily handling demolding of complex shapes, they are a reliable choice for the mold-making industry. Manufacturers can trust in the quality and longevity of their products, knowing that they are investing in a solution that will stand the test of time and deliver consistent results. As a molds manufacturer, we are committed to providing quality their, ensuring that our clients can overcome their pain points and achieve success in their endeavors.

English

English عربى

عربى Español

Español Français

Français