Walk into any paint store or supermarket and you'll see buckets in every size and color —holding paint, food, detergent, or even pet supplies. Behind these everyday containers lies an invisible hero: the bucket mold. Understanding how it is made explains a lot about why some buckets last for years while others crack after a few uses.

What Exactly Is a Bucket Mold?

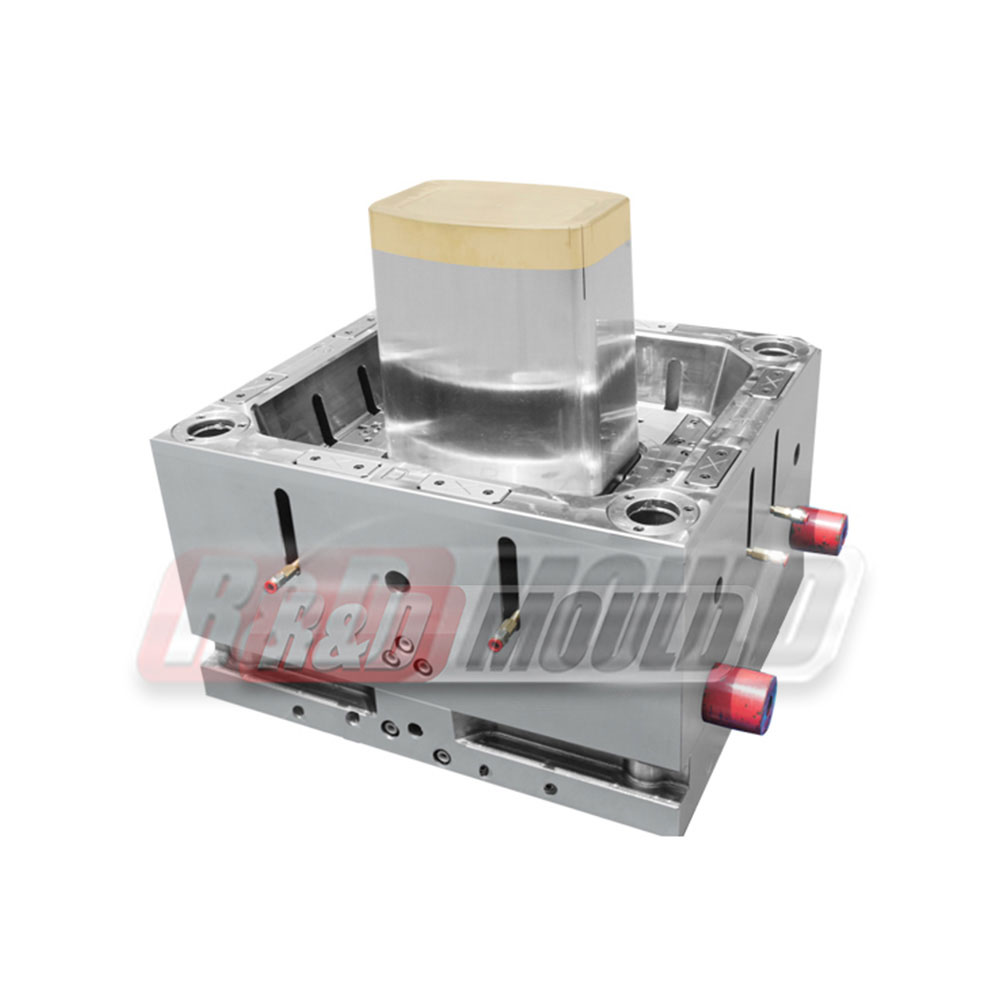

It is a precision tool used in injection molding machines to create plastic buckets. It defines the bucket's shape, wall thickness, handle position, and even surface texture. Each mold can produce thousands or even millions of identical products before it wears out.

Why the Design Stage Is So Important

Professional design is the foundation of a durable and efficient bucket mold. The design decides how well plastic flows inside the mold and how easily it cools and releases. Manufacturers like R&D Mould in China pay close attention to cooling system layout. Cooling channels are placed about 15mm below the molding surface, with a diameter larger than 12mm to keep water flowing smoothly.

This level of detail may sound small, but it directly affects how quickly the plastic cools and how beautiful the final bucket looks. A poor cooling design often results in visible marks, slower production, or even warping.

The Role of Steel Selection

Not all steel is the same. The steel chosen for a bucket mold decides how long it lasts and how stable the product quality remains. For molds designed to run about one million cycles, 2738 steel with HRC35—38 hardness is a popular choice. When the goal is three million or more cycles, 2344 steel with HRC45—48 hardness offers better durability.

Some customers request even faster molding and shorter cooling times. In those cases, manufacturers may add beryllium copper inserts at critical positions like the core top and cavity bottom to boost heat transfer.

Precision Means Quality

Even a tiny misalignment in the core or cavity can make the bucket wall uneven or the body off—center. This is one of the many common but costly problems in the industry. That's why experienced bucket mold manufacturers rely on great machining and testing equipment to keep tolerances tight. A well—made mold not only produces more consistent products but also runs longer without maintenance.

Beyond Paint Buckets

Modern bucket mold manufacturers no longer focus only on standard paint buckets. They produce molds for all kinds of packaging containers —thin—wall food containers, IML (in—mold labeling) containers, PET preforms, bottle caps, and even cutlery molds. Each product type demands slightly different design priorities, whether it's cooling efficiency, cycle time, or labeling accuracy.

Why It Matters to You

If you're in the packaging or plastic product business, choosing the right bucket mold partner is more than a purchase —it's an investment in quality and efficiency. A well—designed mold runs faster, wastes less material, and produces cleaner, more appealing products. That means your production line stays stable and your customers stay happy.

Bucket molds may seem simple, but they combine engineering, materials science, and real—world experience. Behind every smooth, strong bucket is a team of designers, machinists, and engineers who understand what it takes to turn molten plastic into a product people use every day.

English

English عربى

عربى Español

Español Français

Français