Across industries, from household goods to automotive parts, every plastic component starts with one crucial step — the making of a mould. Behind these precise tools stand experienced manufacturers who shape ideas into reality. A China Mould factory plays a key role in this process, offering the mix of technology, craftsmanship, and affordability that global companies look for.

How a China Mould Factory Brings Ideas to Life

When a customer approaches a China Mould factory, the process doesn't start with machines — it begins with a design. The factory's engineering team studies the 3D product model, refines the parting lines, and checks for draft angles, wall thickness, and material behaviour. This design stage ensures that when production starts, every detail aligns with how the product will perform in the real world.

At R & D Mould Co., Ltd., established in 2008, this early—stage collaboration is key. The company provides 3D product design, rapid prototyping, and detailed 2D and 3D drawings. Each project is handled to create a functional, efficient mould that delivers consistent quality.

Mould Manufacturing Step by Step

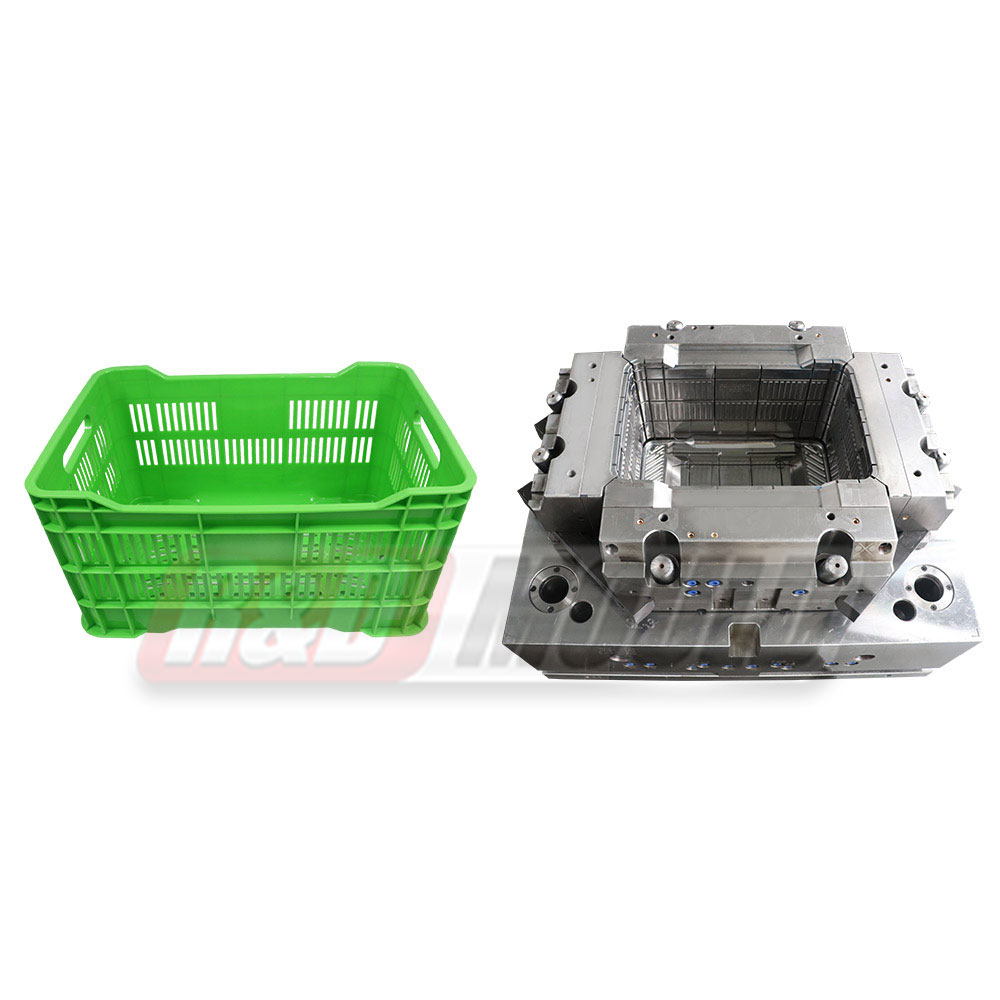

Once the design is approved, the machining begins. A typical China Mould factory uses CNC milling, EDM, polishing, and fitting to build each part of the mould. Skilled technicians work with tight tolerances so the final tool fits good together. Cooling channels, ejector systems, and runner layouts are carefully tested to keep production stable.

R&D Mould focuses on injection and blow moulding moulds used in many industries: household products, automotive parts, medical components, pipe fittings, and packaging containers. Each category comes with different technical needs. For example, a medical mould requires high precision and smooth surfaces, while a packaging mould values fast cycles and easy maintenance.

Balancing Quality and Cost

One of the main reasons companies choose a China Mould factory is the balance of quality and price. With over a decade of manufacturing experience, R&D Mould combines great equipment with practical production methods. This means the customer gets reliable moulds without overpaying for unnecessary complexity.

The real value, however, is in the communication. A good factory provides regular project updates, sample testing reports, and improvement suggestions. That partnership saves time and reduces errors before mass production begins.

What Makes a China Mould Factory Reliable

Many buyers look for more than just a quote — they want confidence. A reliable China Mould factory shows it through transparency and professionalism. Does the team share design suggestions? Are materials and hardness levels clearly explained? Are delivery timelines realistic?

At R&D Mould, engineers select steel grades that match project goals. For long—lasting moulds, they often use steels like 2344 or 2738. Every mould is tested before shipment to verify fitting, cooling, and part ejection. These steps may seem routine, but they protect customers from costly adjustments later.

As manufacturing continues to evolve, a China Mould factory is no longer just a supplier —it's a development partner. From the early 3D sketch to final delivery, the process combines engineering accuracy with creative problem—solving.

For businesses searching for a trustworthy partner in plastic mould manufacturing, China's factories offer the experience, technology, and teamwork needed to bring ideas into production reality. And behind every successful project stands a factory like R&D Mould — where precision meets collaboration.

English

English عربى

عربى Español

Español Français

Français