An Automotive Mould project often starts with a clear idea of the part's appearance and functional needs, but buyers quickly find that the real challenge lies in how the mould is designed, machined, and supported during production. Many sourcing managers compare Automotive Mould Manufacturers not only by quotation numbers but by their ability to meet production goals, handle complex geometries, and offer dependable technical support. These factors influence the overall workflow more than many expect.

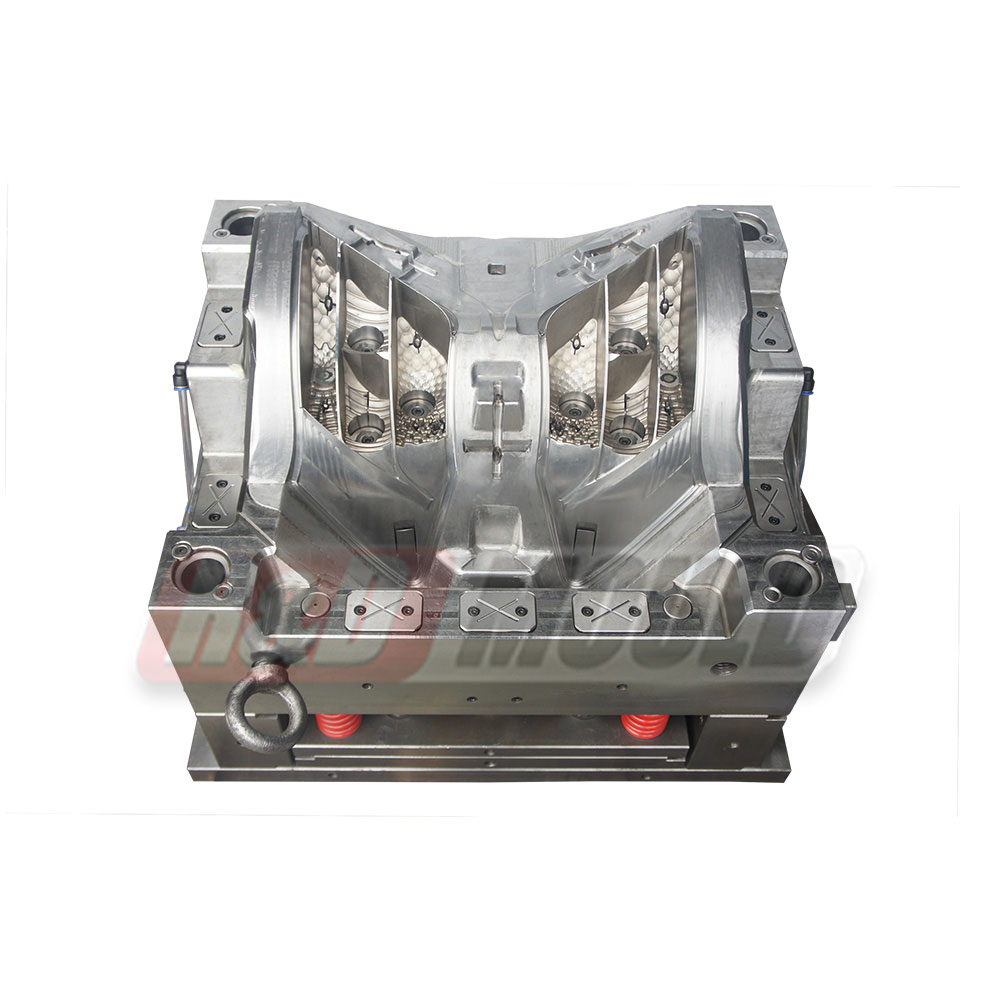

For items such as rear lamp moulds, spray cap moulds, or other precision automotive components, customers pay attention to structural strength, cooling balance, and machining accuracy. They want moulds that run smoothly under high-speed injection and work well with automated pickers or robot demolding. Below are several angles that often shape a buyer's decision-making process.

1. What design clarity means for functional and optical parts

Buyers who manage automotive production know the importance of design precision. A rear lamp mould, for example, must meet strict surface and optical requirements. That is why suppliers often use 1.2343 steel for the cavity and core, combine it with hot runner valve gate systems, and build the mould around stable hardness levels. These details help customers avoid repeated polishing, surface marks, or deformation after long cycles.

A reliable Automotive Mould also supports consistent part release. Automated demolding, such as robot take-out, has become common, and customers prefer suppliers who can integrate a smooth ejection structure from the beginning. Automotive Mould Manufacturers with experience in functional surfaces, transparent materials, or thin edges usually provide more accurate design guidance before tooling starts.

2. Steel selection and expected mould life

Many buyers ask about mould life during the early communication stage because it directly influences project budgeting. Automotive components, especially lighting parts, run large orders that require steady mould performance. A common reference point is around 500,000 shots for a rear lamp mould.

Manufacturers that work across different automotive plastic categories often provide a clearer explanation of steel choice and heat treatment. This helps customers predict how the mould will behave during repeated heating and cooling, particularly in high-speed injection environments. The clearer these details are, the easier it is for sourcing teams to plan long-term production schedules.

3. Machining precision that supports clean appearance and fit

Machining accuracy is a major concern for customers dealing with exterior or optical automotive parts. A small deviation can affect the way two components fit, or how a lamp reflects light. Buyers often ask for details on CNC accuracy, EDM finishing, and polishing steps. They want to know how the supplier controls tolerances so the part maintains clarity and dimensional consistency over time.

Automotive Mould Manufacturers with strong machining capability usually share data like electrode design notes, processing steps, and surface requirements before steel cutting. Customers appreciate this because it reduces the risk of rework during trials. A well-machined Automotive Mould also supports steady ejection and lowers the chance of surface scratches or stress marks.

4. Technical support that solves problems during production

After-sales service plays an important role in choosing a supplier. Many buyers mention that engineers who can quickly help troubleshoot injection settings, cooling adjustments, ejection timing, or robot alignment save them many hours of downtime. A supplier offering full service—from the earliest sketch to a functioning part in the buyer’s hand—gives customers stronger confidence.

Some customers also value rapid prototyping before approving the final mould design. It helps verify the part structure and prevents unnecessary modifications later. When Automotive Mould projects include OEM requirements, special surface needs, or complex 2D drawings, a supplier with rich project experience can interpret the details more accurately.

A management system, paired with stable delivery time and reasonable pricing, makes the cooperation smoother. Buyers handling multiple automotive programs often prefer a supplier who understands their standards and can support long-term production with consistent communication.

English

English عربى

عربى Español

Español Français

Français