Cap closures look simple, but the mould behind them decides how smoothly a line runs. A well-structured Cap Mould supports stable injection cycles, consistent cap shape, and reliable fit on HDPE or PET bottles. In beverage, dairy, and fruit juice lines, even small size deviations can create sealing issues or slow down capping machines.

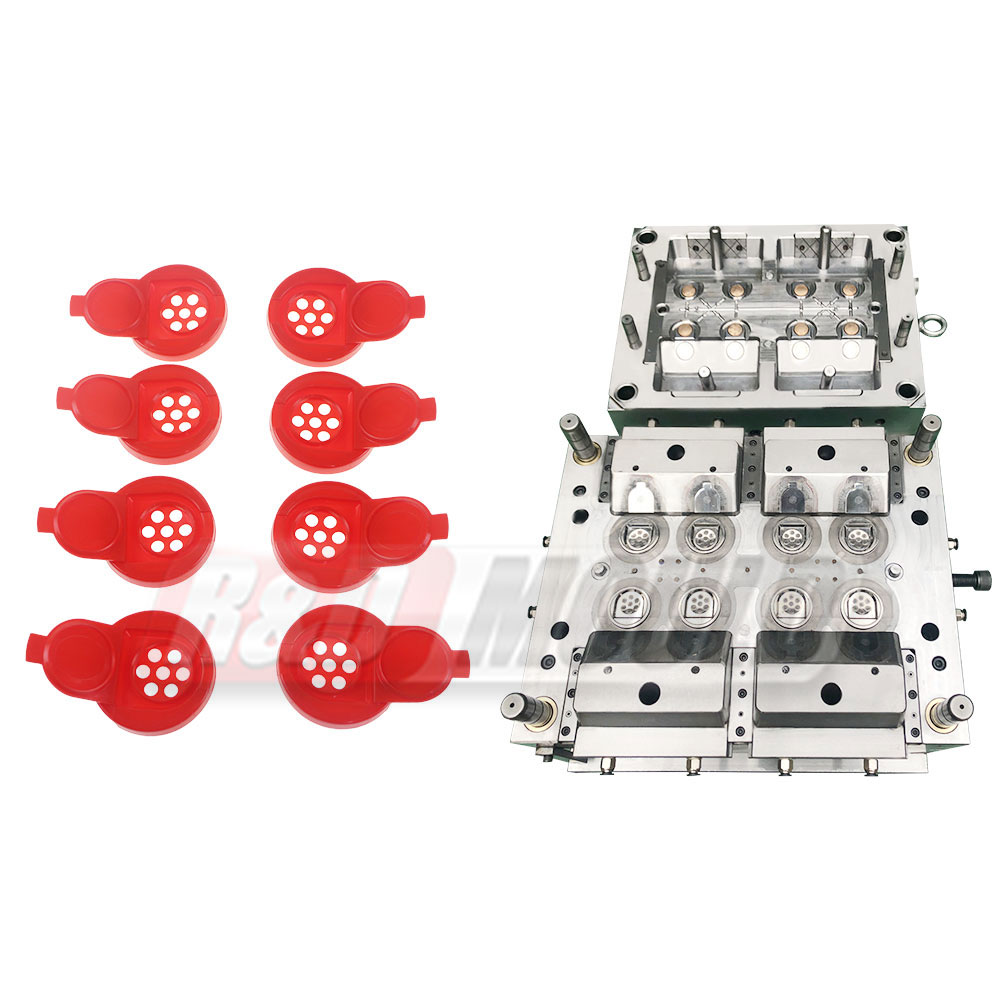

Modern injection-based cap mould solutions are designed with multi-cavity layouts to support mass production. This approach helps factories keep output stable without increasing machine count. For larger formats such as 3 or 5 gallon bottles, cavity balance and mould rigidity become even more important. Cap Mould Manufacturers usually evaluate bottle type, cap structure, and machine capacity together before fixing the design.

Cooling layout is another hidden factor. Optional water cooling systems shorten each cycle while keeping the mould temperature even. That balance helps caps release smoothly and reduces deformation during ejection, especially for flip-top and screw cap structures.

Why Precision and Steel Choice Matter in a Cap Mould

Precision is not only about appearance. Tight tolerance inside a Cap Mould controls thread accuracy, inner seal shape, and wall thickness. These details directly influence how the cap performs during filling and transportation. great CNC machines, EDM processing, and high-speed engraving are commonly used to keep dimensions stable across every cavity.

Steel selection plays a long-term role. Materials such as S136, 2316, and H13 are widely used because they support long mould service life and stable surface conditions. With proper design and processing, a single mould can reach around five million shots while keeping cap quality consistent. This is one reason experienced Cap Mould Manufacturers pay close attention to steel sourcing rather than focusing only on price.

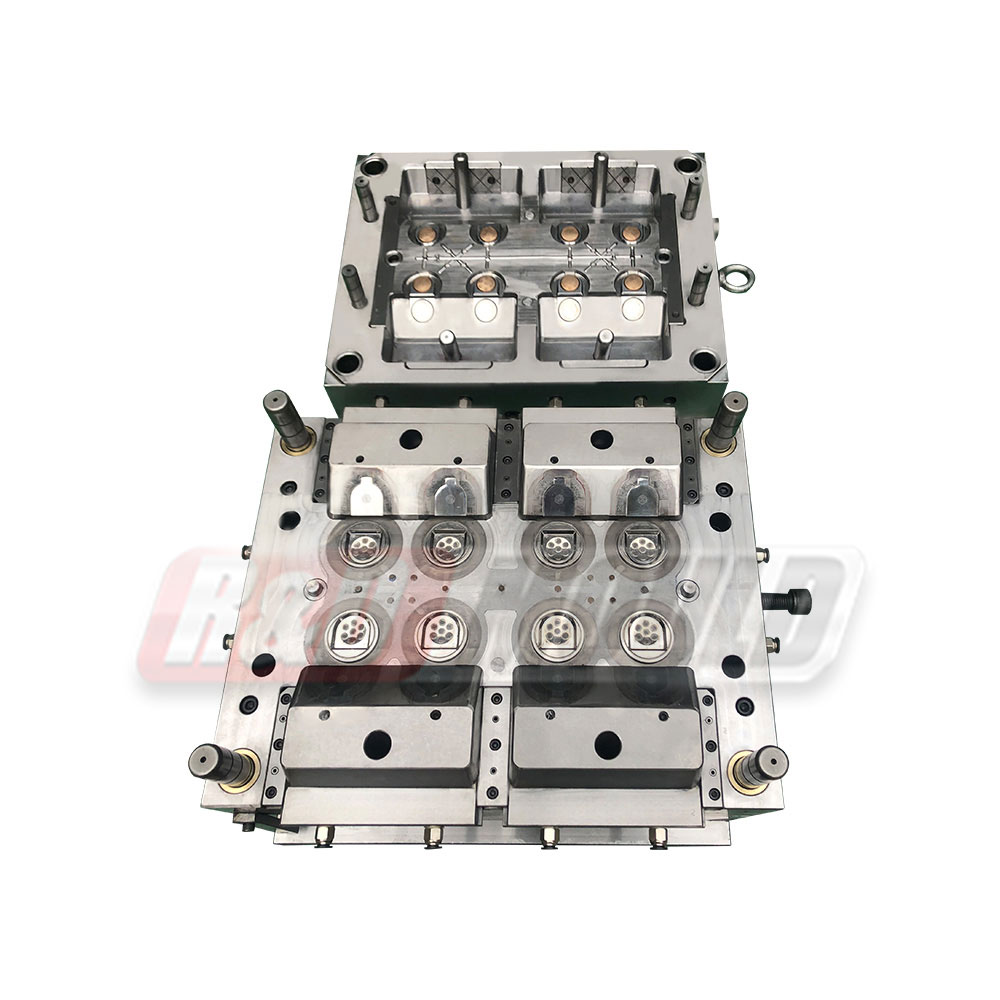

Interchangeable core inserts are another practical detail. When wear happens in specific areas, inserts allow targeted replacement instead of full mould disassembly. That structure supports smoother maintenance planning and keeps production interruptions shorter.

How Cycle Time and Structure Influence Output

Fast cycle time is not achieved by speed alone. It comes from balanced cavity layout, stable hot runner systems, and controlled temperature. A well-matched hot runner and temperature controller keep melt flow even, helping each cavity fill at the same pace. This consistency reduces pressure fluctuation and improves repeatability.

Automatic ejection systems are standard for modern cap closure moulds. They support smooth demoulding and reduce manual intervention. Self-lock structures are often added to avoid mould eccentricity during operation, which helps protect alignment over long runs.

Multi-cavity Cap Mould solutions are widely used for beverage caps because they fit continuous production models. The key is matching cavity number with injection machine capacity. Cap Mould Manufacturers often suggest cavity layouts based on expected output, mould life goals, and machine tonnage, rather than offering a fixed configuration.

Clear technical communication shortens development cycles and supports smoother trials. When mould design, material choice, and machine condition are aligned from the beginning, the mould performs steadily in real production rather than only during testing.

A Cap Mould is not just a tool; it is part of the production system. Choosing the right structure and working with capable Cap Mould Manufacturers helps keep output stable, maintenance manageable, and cap quality consistent across long production runs.

English

English عربى

عربى Español

Español Français

Français