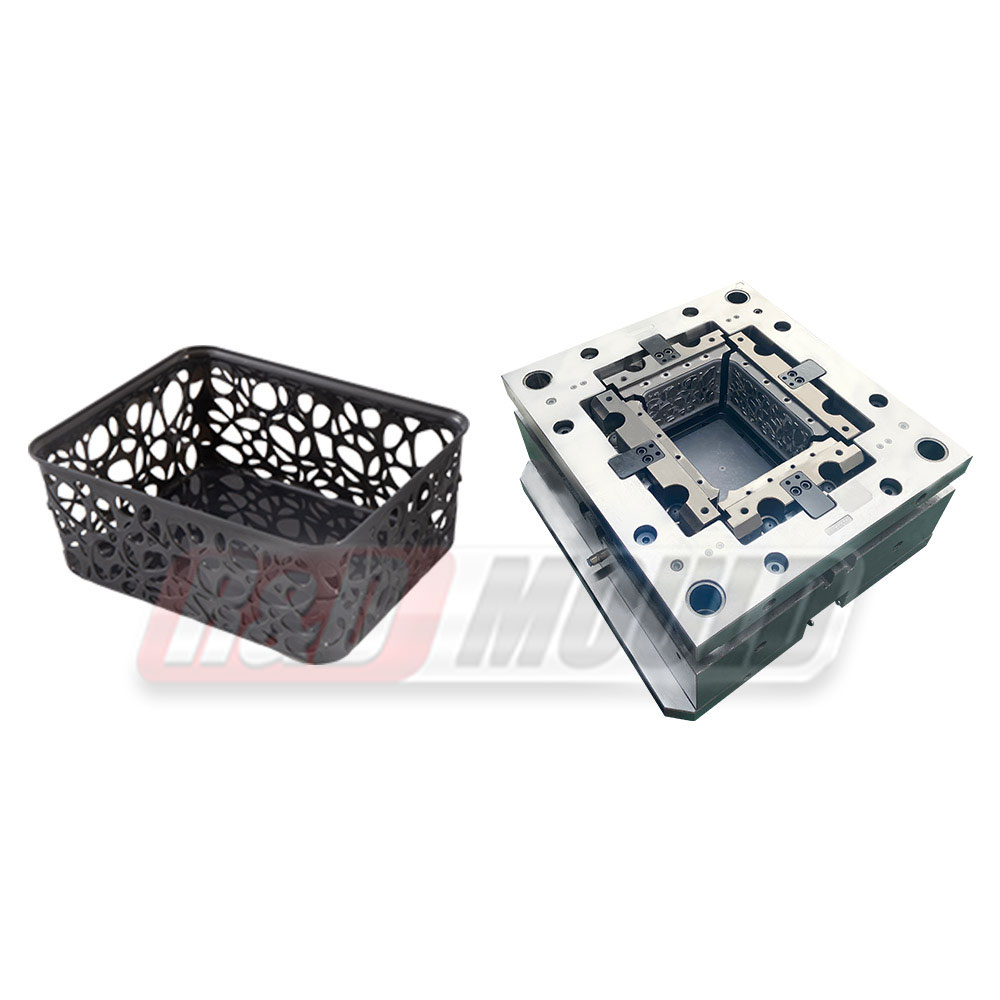

Basket products look simple on the surface, but their mould structure is often complex. Many baskets require uniform wall thickness, smooth edges, stable shape, and consistent appearance across repeated cycles. A Basket Mould is not just about shaping plastic; it directly influences production rhythm, surface quality, and long-term usability of the basket itself.

Factories developing baskets for shopping, laundry, or storage often face similar challenges: uneven cooling, visible flow marks, deformation after demoulding, or slow cycle times. These issues usually come from early design decisions rather than processing mistakes later.

How Cooling Design Impacts Basket Mould Performance

Cooling is one of the core concerns in Basket Mould production. Basket structures usually include dense ribs, multiple holes, and thicker edges. Without proper cooling balance, shrinkage inconsistency and surface marks may appear.

In long-term basket mould projects, beryllium copper inserts are often used in the core top area. This material improves heat transfer, helping molten plastic cool more evenly. Faster heat dissipation supports a steady cycle rhythm and keeps the basket shape stable after ejection.

Cooling channels also need careful planning. Channels arranged on both sides of the core and cavity help reduce visible melting lines around holes and ribs. Poor cooling layout often results in repeated adjustments during trial stages, which slows down project timelines.

Managing Holes and Ribs in Basket Mould Design

Plastic baskets usually include many air holes for ventilation and weight reduction. These holes bring design challenges. Improper parting surface placement may cause flashing, blocked holes, or rough edges.

When designing a Basket Mould, the R angle around holes and ribs must be reasonable. Sharp transitions tend to cause stress concentration and surface defects. A smoother transition supports cleaner demoulding and a consistent surface finish.

Experienced mould teams pay close attention to these small structural details during the design stage rather than relying on later corrections.

A Basket Mould Manufacturer with real production exposure usually recommends materials based on basket structure and expected output rhythm, not just price.

Customisation Needs in Basket Mould Projects

Standard basket designs seldom fit all applications. Shopping baskets, laundry baskets, and storage baskets differ in depth, hole layout, load expectations, and stacking behaviour. Custom Basket Mould development allows these details to be adjusted early.

Customisation may include changes in rib distribution, handle structure, logo area, or surface texture. Injection balance, gate position, and cooling layout often need to match these changes.

R&D Mould, as a basket mould manufacturer based in China, provides customised basket mould service, including plastic injection basket mould solutions. Over 15 years of experience from various basket categories has helped refine how these custom elements are integrated without disrupting mould stability.

Addressing Common Issues During Basket Mould Production

Several issues tend to repeat across basket mould projects. Melting lines around holes, deformation after cooling, and uneven gloss are among the common ones. These problems often trace back to a cooling imbalance or improper venting.

Reasonable venting design helps trapped gas escape during injection. Without it, surface marks and incomplete filling may appear, especially around dense rib areas.

By adjusting parting lines, vent slots, and cooling routes during the design phase, later troubleshooting can be reduced.

A Basket Mould plays a direct role in product appearance, production rhythm, and long-term mould stability. From cooling structure and material choice to hole layout and parting surface design, each detail affects how smoothly basket production runs in real manufacturing conditions. With accumulated experience across different basket applications, a capable Basket Mould Manufacturer can translate functional needs into practical mould solutions. By focusing on cooling efficiency, structural balance, and customisation readiness, basket mould projects can move from design to stable output with fewer adjustments and clearer results.

English

English عربى

عربى Español

Español Français

Français