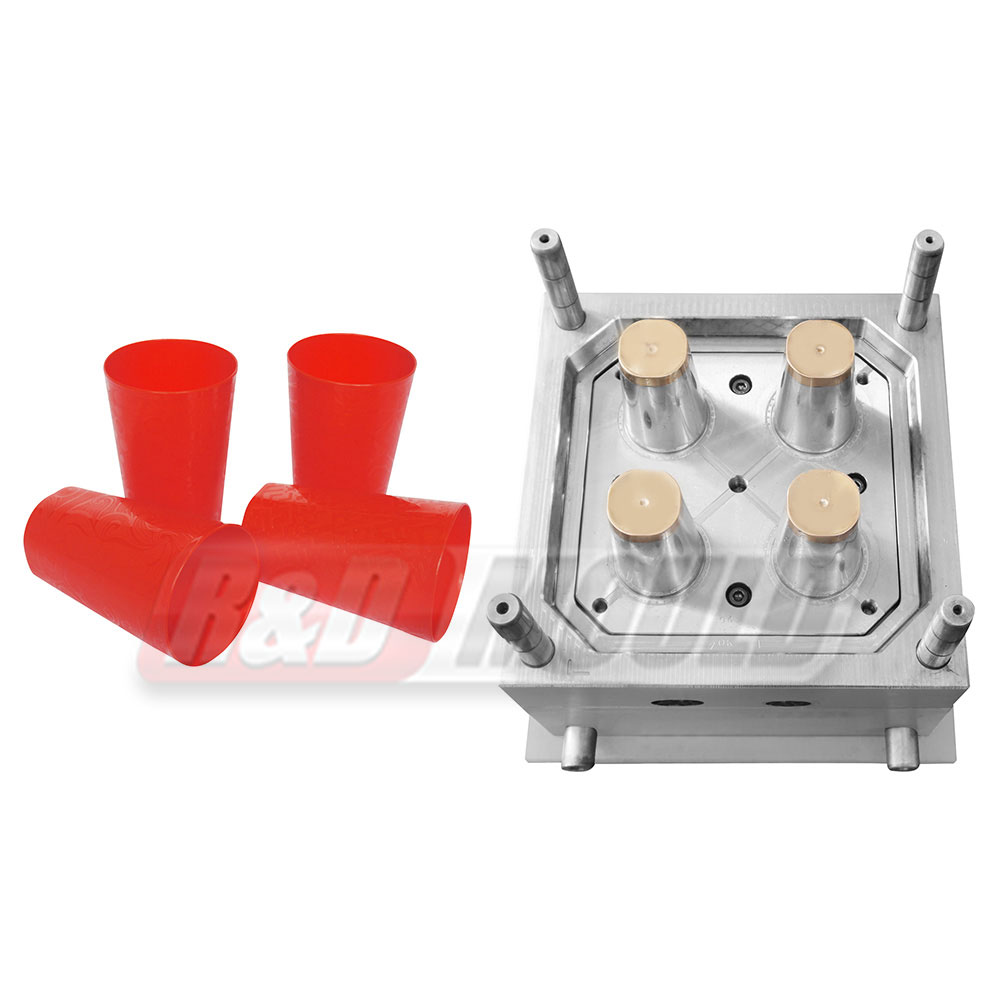

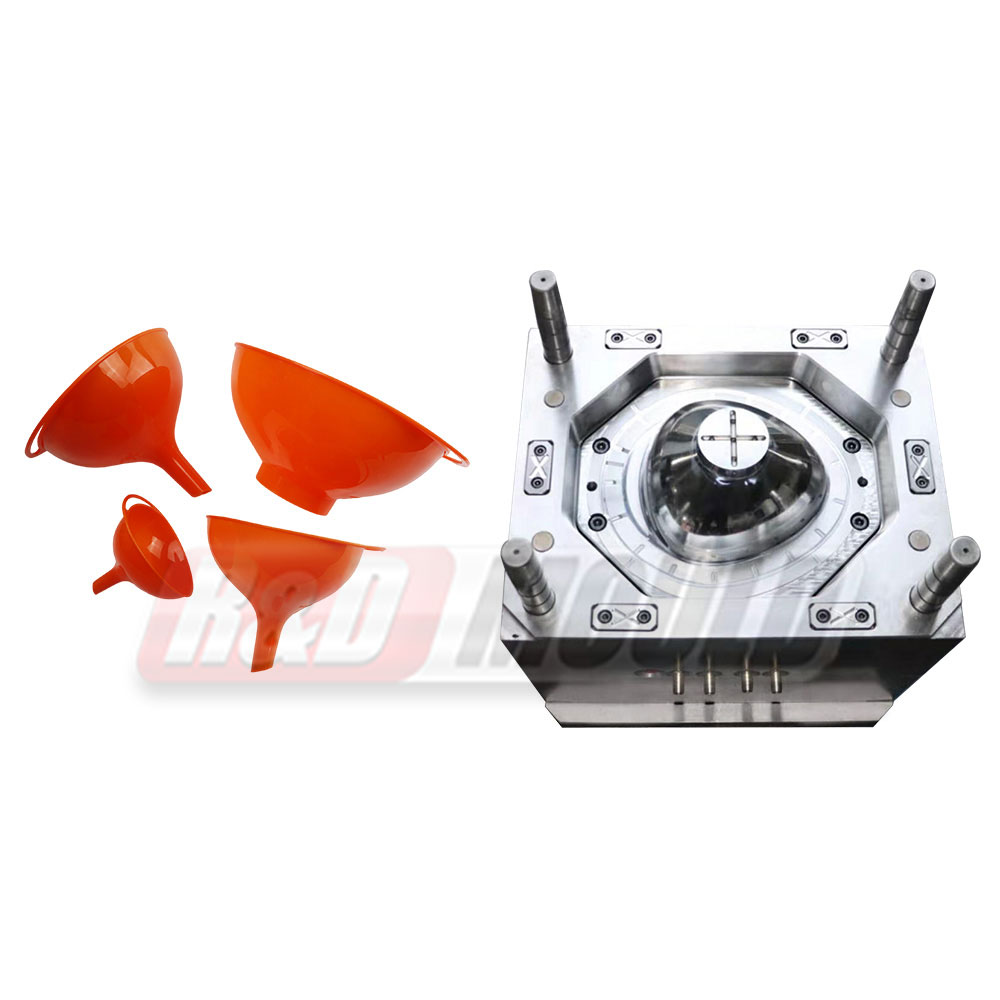

| Mold Name | Water Pot Mould |

| Plastic Material | PP |

| Mold Cavity/Core Steel | P20 |

| Runner /Gate System | Hot Runner |

| Manufacture Time (Day) | 45 Days |

| Mold Life | 500,000 Shots |

| Machine Size | 780 Ton |

| Demolding | Full Automatic |

R&D Mould has more than 15 years’experience for making water pot moulds. We provide you excellent design and manufature with competitive price. We also provide perfect after-sales service so that you have no worries.

English

English عربى

عربى Español

Español Français

Français.jpg)

.jpg)

.jpg)