|

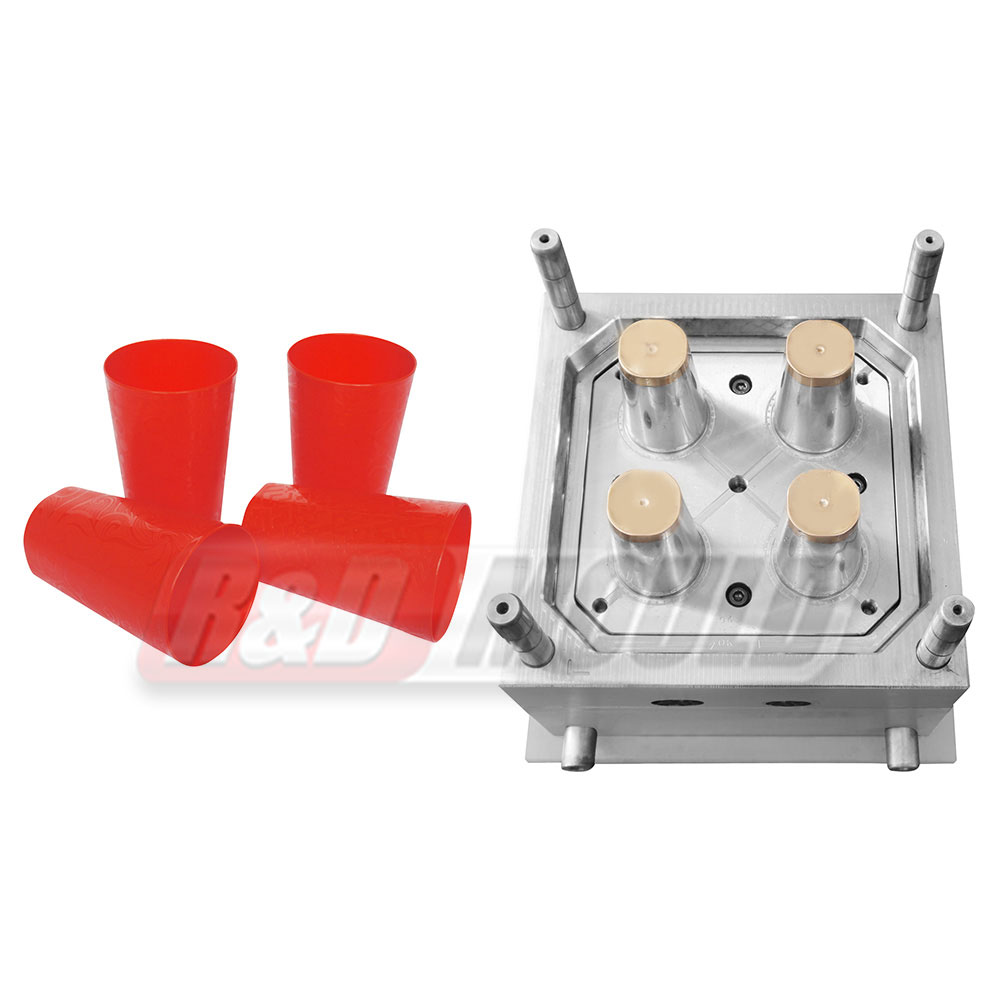

Product Name |

Coffee Cup Mould |

|

Product Material |

PP |

|

Mould Material |

H13 |

|

Mould Cavity |

2 |

|

Runner Type |

Hot runner |

|

Mould Life Guarantee |

1000,000shots |

|

Manufacture time (day) |

45 days |

|

Demoulding |

Full automatic |

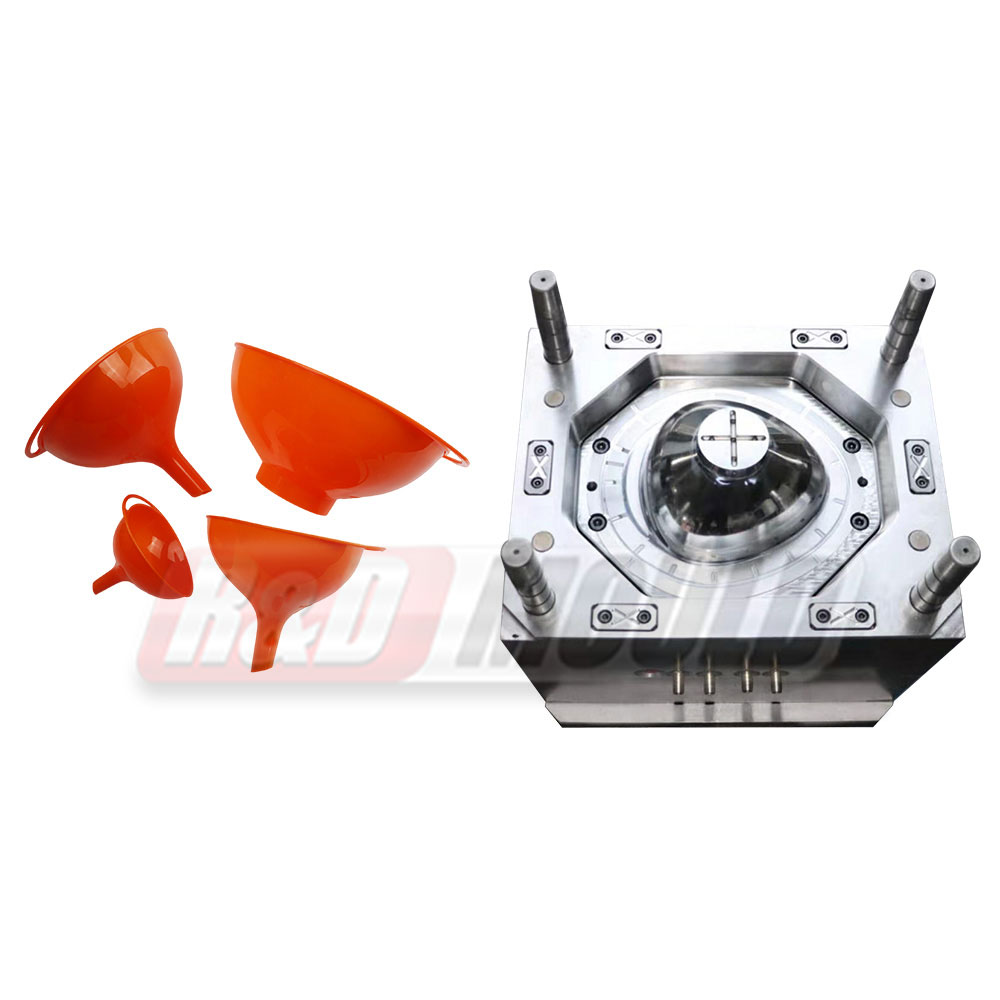

R&D Mould takes great pride in its extensive experience of over 15 years, specializing in crafting top-quality coffee cup moulds. As a leading player in the mould industry, our dedication to precision and innovation has made us the preferred choice for coffee cup moulds. We keep ourselves abreast of market demands and ever-evolving trends, continually investing in advanced technologies and modern machinery to ensure our customers receive the best products.

Our team of skilled mould designers and engineers collaborates closely with clients, offering personalized solutions tailored to their specific requirements. We are committed to delivering moulds with exceptional strength and durability, designed to withstand demanding production processes and consistently produce high-quality results.

Our competitive advantages encompass:

1. Comprehensive processing equipment that guarantees efficiency and precision in every step of mould production.

2. A team of experienced and skilled mould designers and engineers, offering industry-leading expertise and creativity.

3. Moulds engineered for remarkable strength and durability, ensuring longevity and cost-effectiveness for our customers.

4. Optimal cooling mechanisms implemented to enhance productivity and minimize production cycle times.

5. Meticulous polishing to achieve flawless finishes, adding a touch of elegance to the final product.

6. Dedicated and reliable after-sales service, providing support and addressing any concerns for a seamless experience.

7. Effective communication channels to foster smooth collaboration and ensure clients' needs are met throughout the process.

8. Prompt delivery of orders, allowing clients to streamline their production schedules efficiently.

9. Competitive pricing for all moulds, making top-notch quality accessible to businesses of all sizes.

Mould Packaging Details:

1. For external packaging, we use standard export wooden cases.

2. Internally, each mould is treated with anti-corrosive oil and wrapped in plastic waterproof film.

3. Spare parts are securely packed together with the mould for shipping convenience.

At R&D Mould, we warmly welcome all plastic mould inquiries, regardless of your manufacturing scale. Our team is fully equipped to assist you with top-notch design, manufacturing, and support, enabling you to achieve your production goals efficiently and cost-effectively. Partner with us today to experience the difference of working with a reliable and dedicated mould manufacturing company committed to excellence.

English

English عربى

عربى Español

Español Français

Français