|

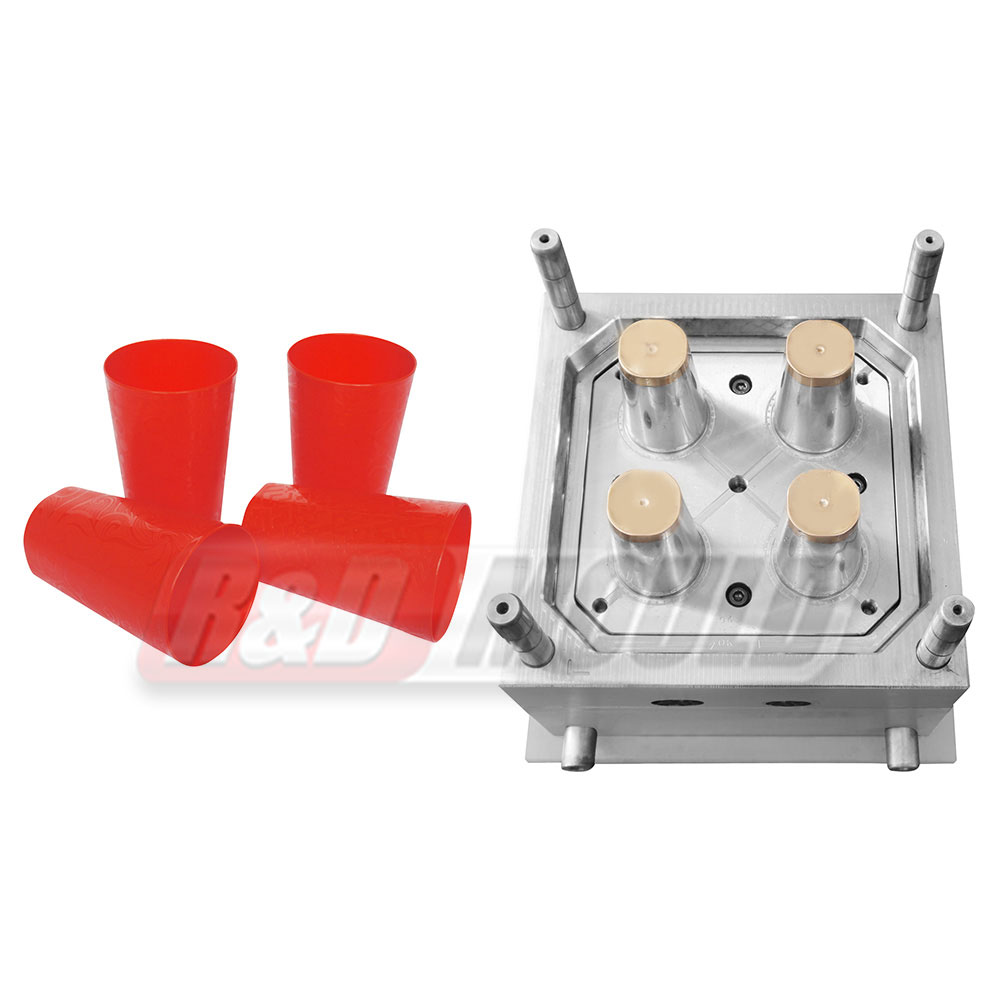

Product Name |

Juice Cup Mould |

|

Product Material |

PS |

|

Mould Material |

S136 |

|

Mould Cavity |

2 |

|

Runner Type |

YUDO hot runner, needle valve |

|

Mould Life Guarantee |

1000,000shots |

|

Manufacture time (day) |

55 days |

|

Demoulding |

Full automatic |

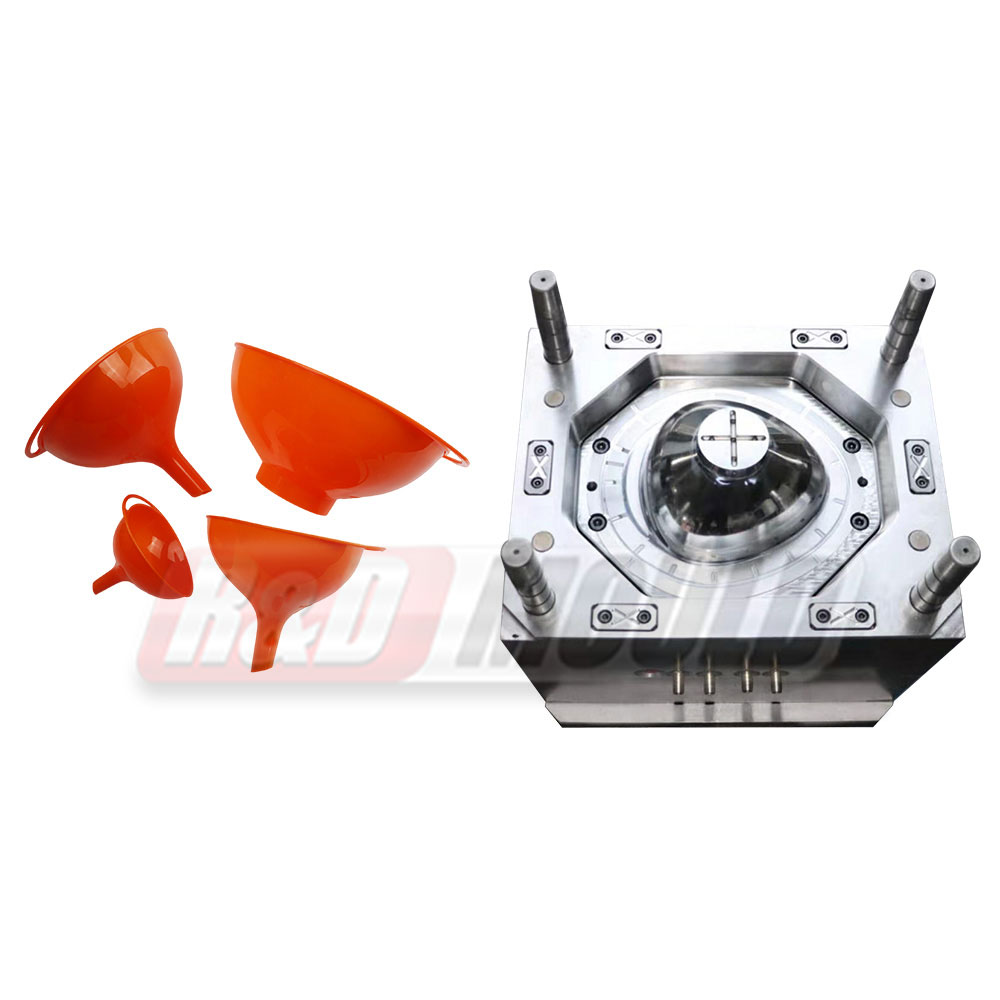

R&D Mould has over 15 years of expertise in crafting top-quality juice cup moulds. We take pride in offering exceptional design and manufacturing at competitive prices, along with unwavering after-sales support for a worry-free experience. R&D Mould has built a strong reputation in the mould industry, and our dedication to precision and innovation has made us a preferred choice for juice cup moulds. With a deep understanding of the market demands and evolving trends, we continuously invest in advanced technologies and modern machinery to ensure our customers receive the best products.

Our team of experienced mould designers and engineers works closely with clients, providing personalized solutions tailored to their specific requirements. We take pride in the high strength and durability of our moulds, which are designed to withstand rigorous production processes and deliver consistent, high-quality results.

Our advantages include:

1. Comprehensive processing equipment.

2. A team of experienced and skilled mould designers and engineers.

3. Moulds with high strength and durability.

4. Optimal cooling mechanisms.

5. Impeccable polishing for flawless finishes.

6. Dedicated and reliable after-sales service.

7. Effective communication for smooth collaboration.

8. Prompt delivery of orders.

9. Competitive pricing for all moulds.

Mould Packaging Details:

1. For external packaging, we use standard export wooden cases.

2. Internally, each mould is treated with anti-corrosive oil and wrapped in plastic waterproof film.

3. Spare parts are securely packed together with the mould for shipping convenience.

Whether you are a small-scale manufacturer or a large industrial player, R&D Mould welcomes all plastic mould inquiries. Our team is ready to assist you with top-notch design, manufacturing, and support to help you achieve your production goals efficiently and cost-effectively. Partner with us today to experience the difference of working with a reliable and dedicated mould manufacturing company.

English

English عربى

عربى Español

Español Français

Français