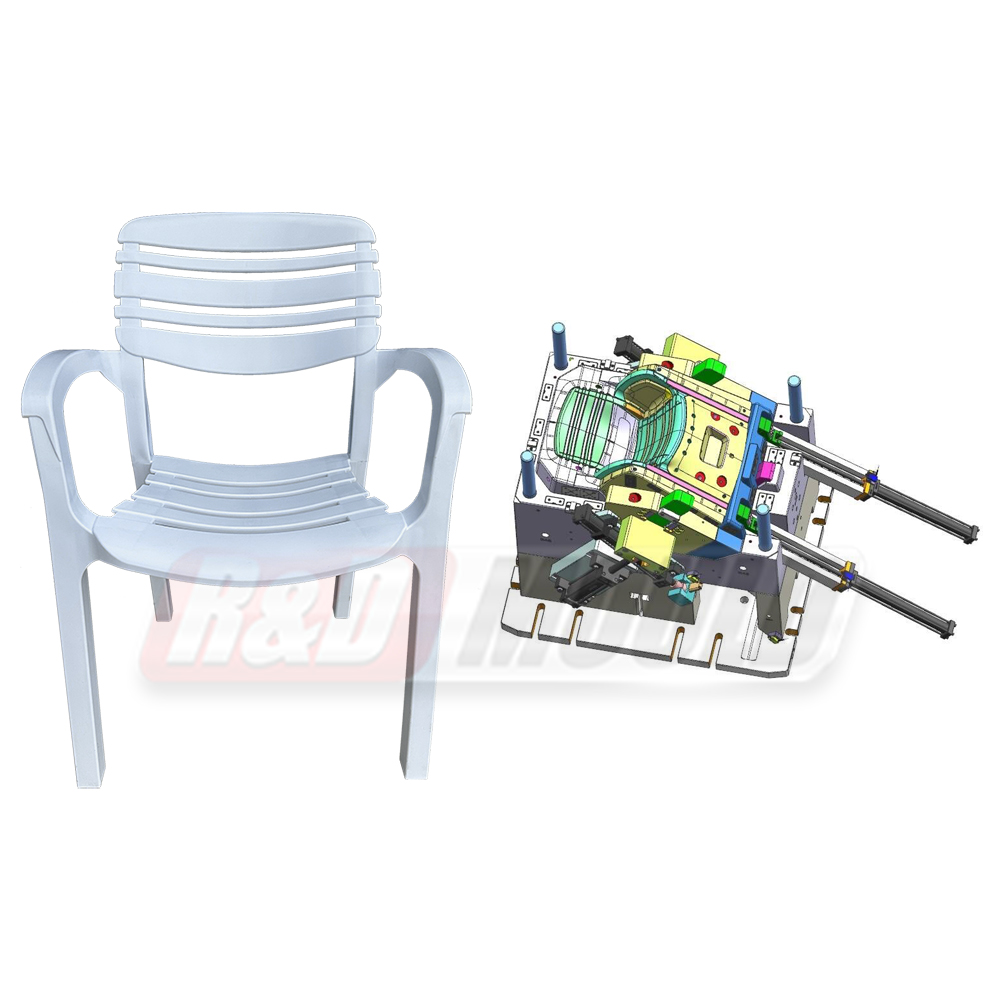

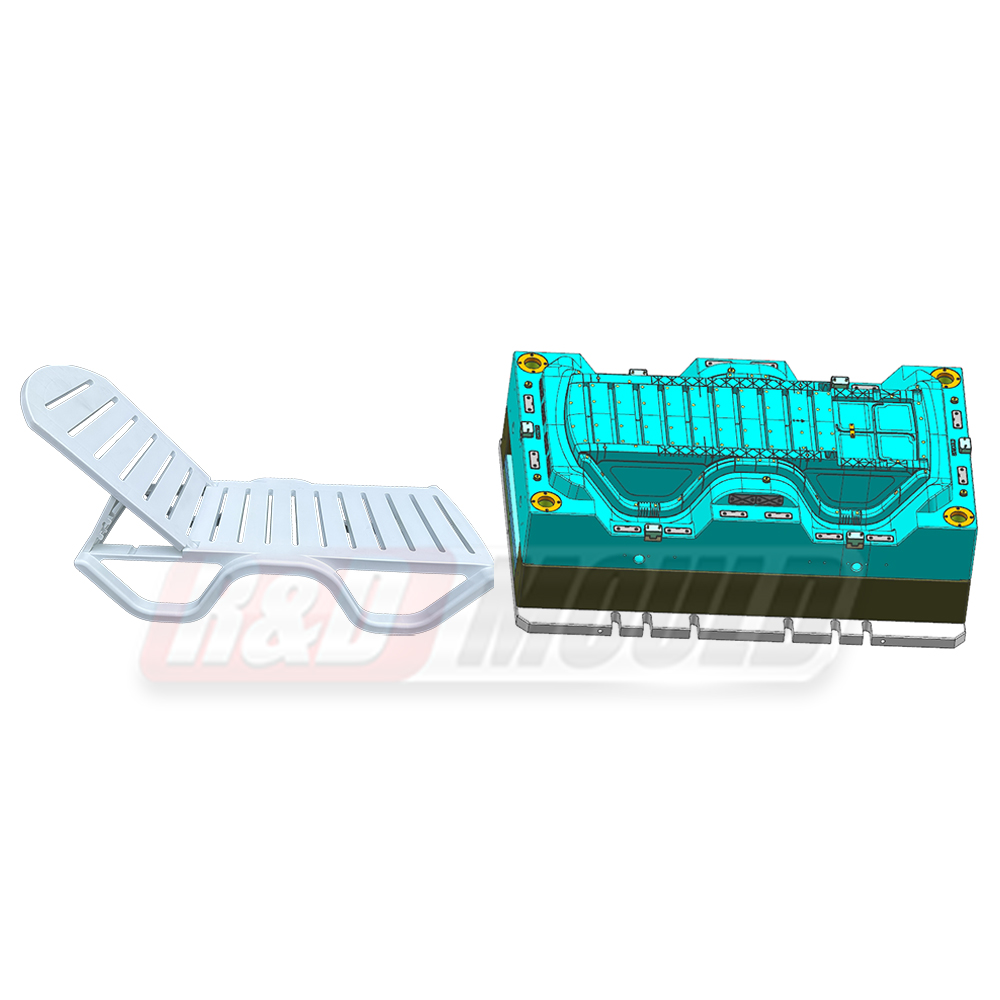

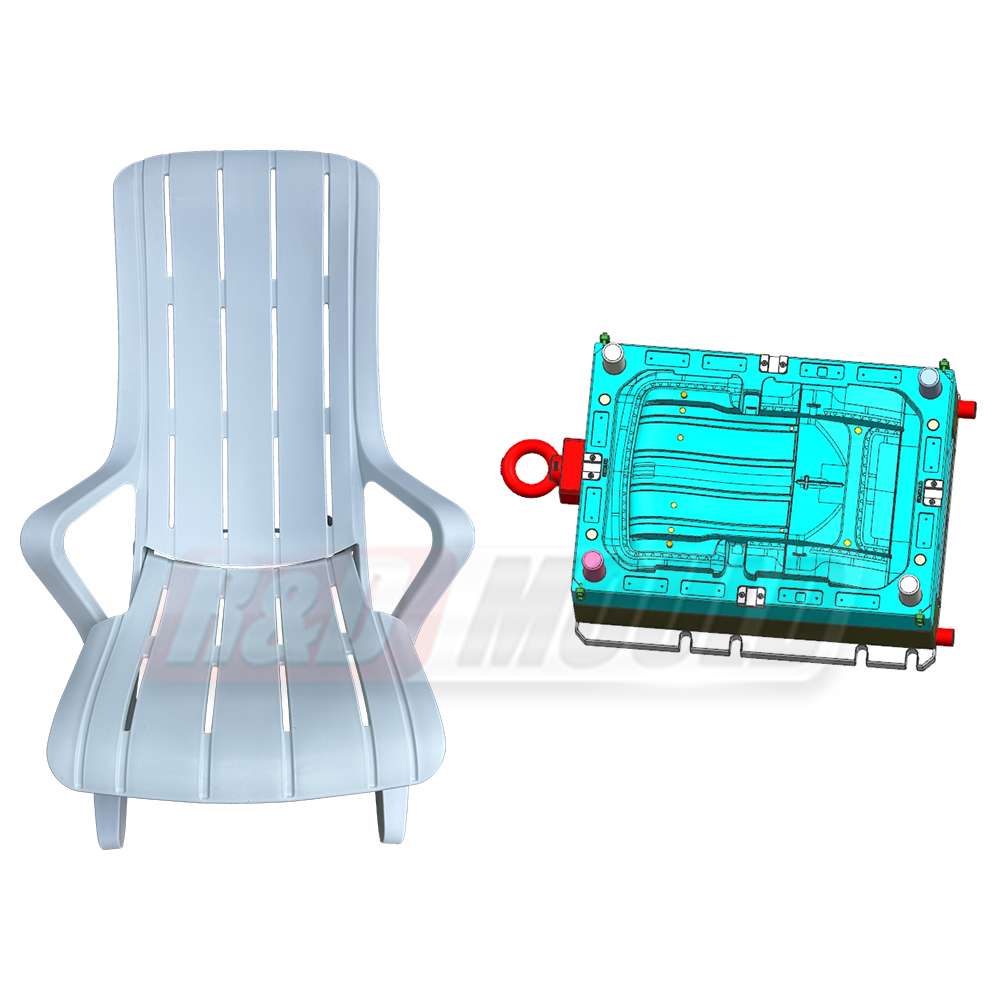

| Mold name | Foldable chair mould |

| Plastic Material | PP |

| Mold cavity/core steel | P20 |

| Runner /Gate system | Hot runner |

| Manufacture time (day) | 70days |

| Mold life | 500,000shots |

| Machine size | 2400Ton |

| Demolding | Robot /Automatic |

Foldable Chair mould

With standard hardness for cavity and core, Germany steel for cavity and core, high speed injection, fully automatic ejection system.With years of working experience and state-of-the-art equipment, we can guarantee our customers high quality products, timely delivery and competitive price.

After-sales Services

Experienced engineers will provide all-round technical solutions to any problems occurred in customers' mould operation.

Advantage

High efficiency, short delivery time, competitive price.You may send your requirement, or 2D, 3D design to us, We can make chair mould exactly as your needs.

R&D Mould offers full service ranging from the original conception to product completion, totally the whole solution from the paper sketch to the functional part in your hand.

1.Mold can produce all kinds of plastic products.

2.Can rapid prototyping.

3.Safe and fast delivery.

4.Quantity, good quality and reasonable price.

5.Support OEM.

6.The high quality service.

7.Customer requirements identified and welcome customer's design.

8.We have rich experience in mold production design and strict management system.

9.Provide the best after-sales service

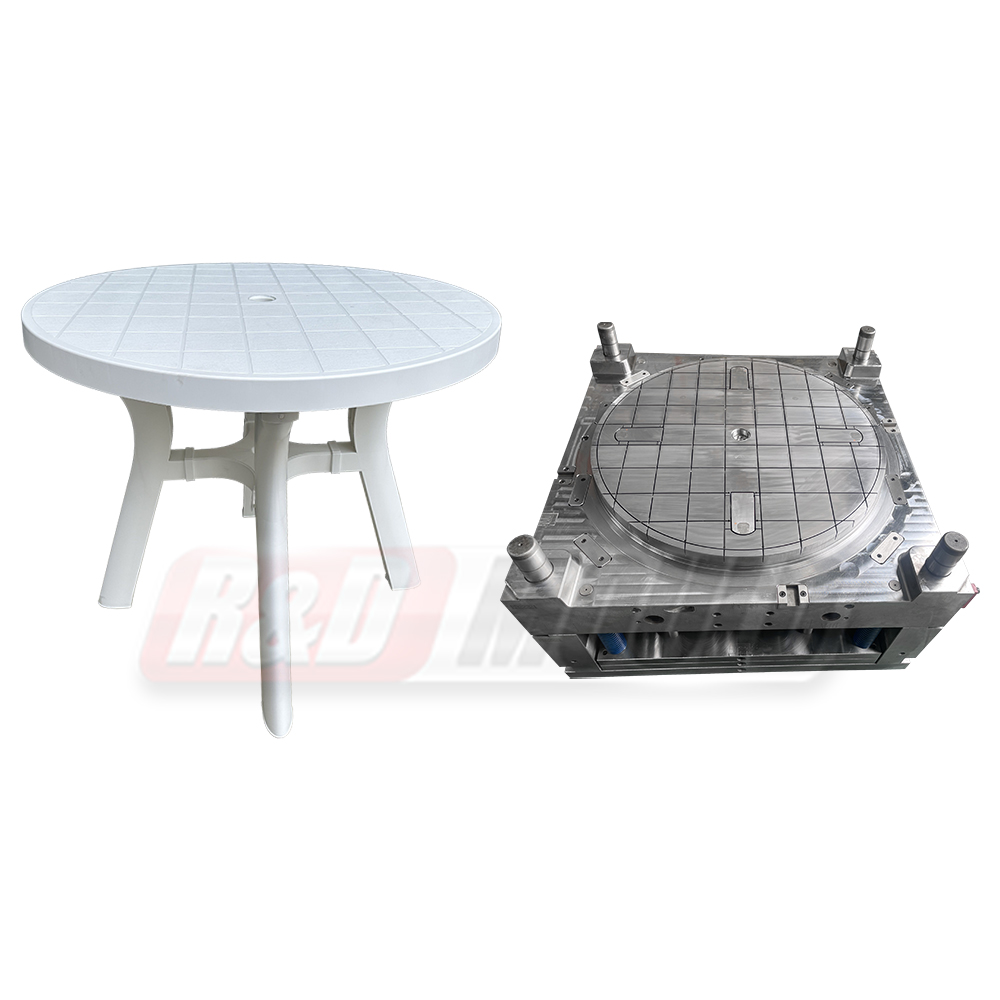

At our company, we specialise in the design and production of high-quality foldable chair molds, tailored to meet the specific needs of our clients. With years of industry experience and advanced manufacturing technology, we are committed to delivering mould solutions that combine precision, durability, and efficiency.

Material and Manufacturing Standards

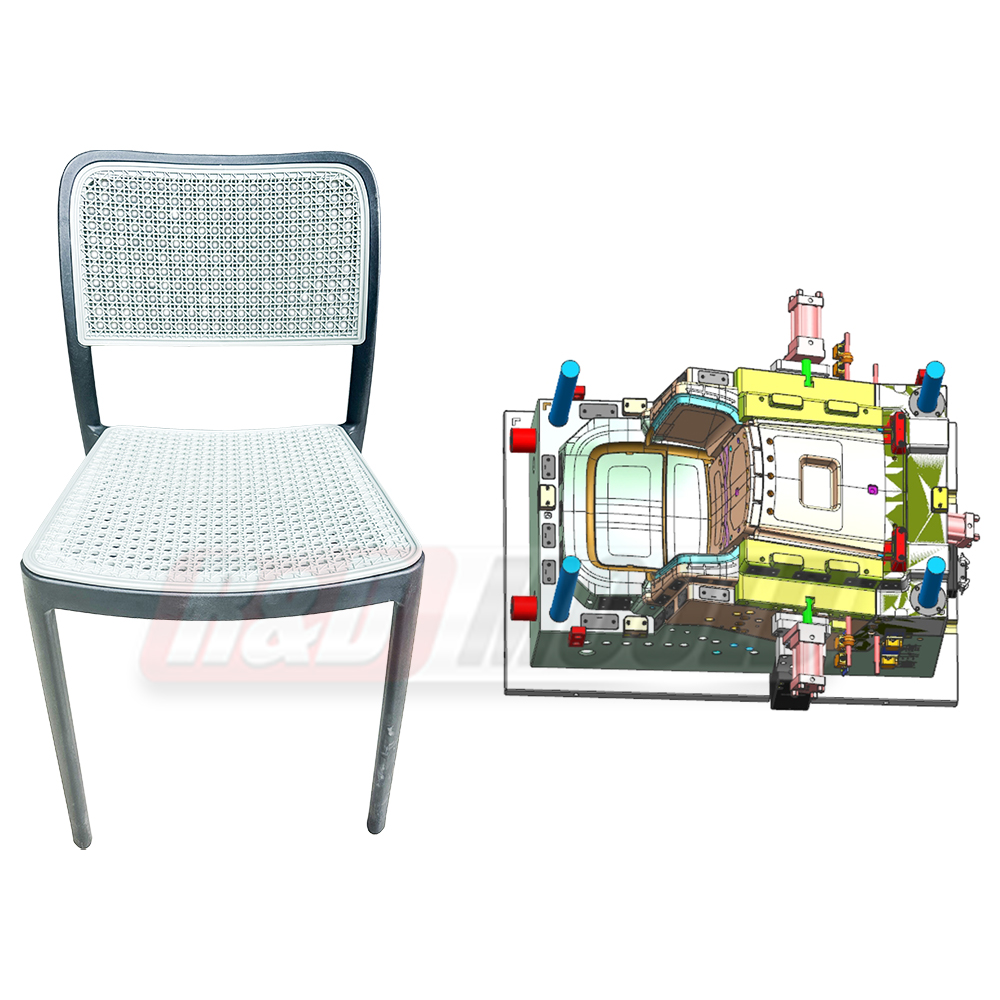

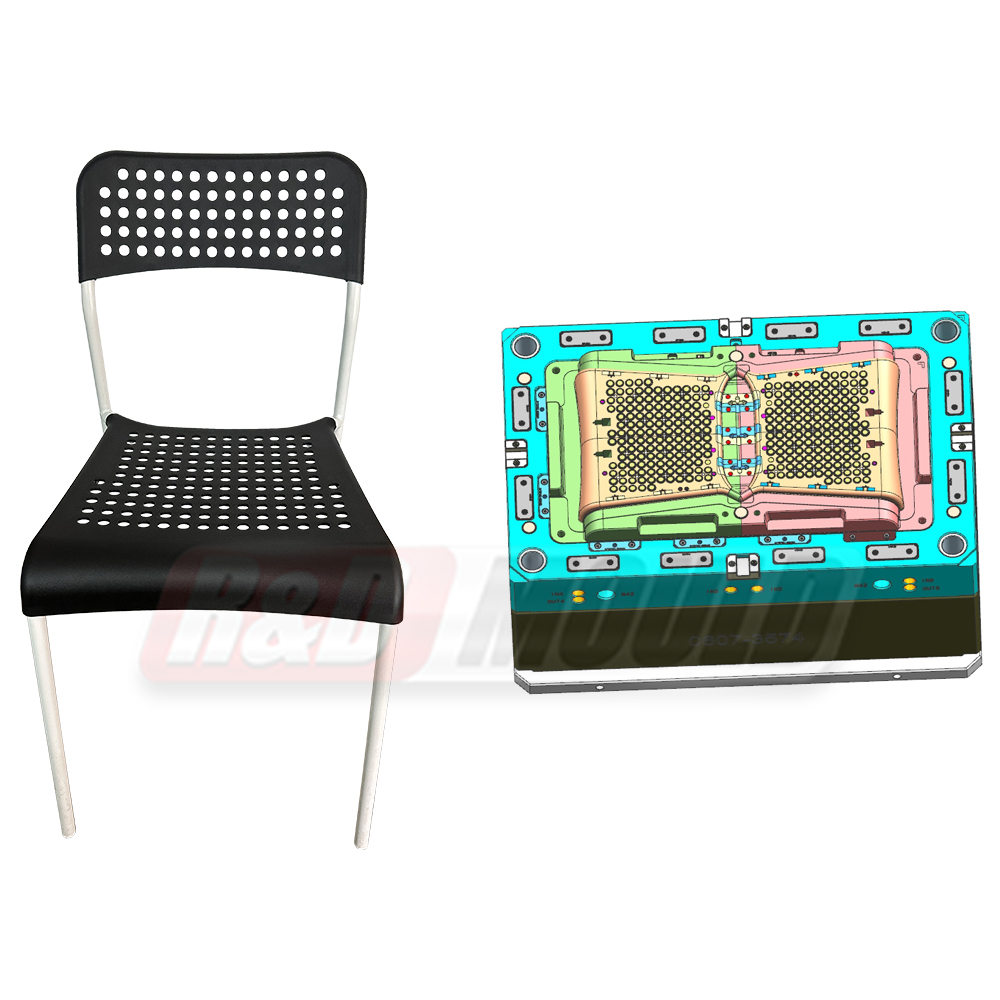

Our foldable chair moulds are manufactured using German steel for both the cavity and core, ensuring superior hardness and wear resistance. This choice of material guarantees longevity and maintains dimensional stability even under demanding production cycles. We employ high-speed injection molding technology coupled with a fully automatic ejection system, which significantly enhances production efficiency and reduces cycle time without compromising quality.

Comprehensive Production Capabilities

We offer a complete mould manufacturing service that covers the entire process from initial concept to finished product. Whether you have a simple sketch or a detailed 2D or 3D design, our experienced engineering team can develop a foldable chair mould that precisely matches your requirements. Our expertise extends to producing moulds for a wide variety of plastic products, allowing us to support diverse applications and product designs.

Rapid prototyping is an integral part of our service, enabling clients to review and refine designs quickly. This approach helps identify potential improvements early in the development phase, leading to better final products and smoother production runs.

Quality Assurance and Delivery

We maintain strict quality control measures throughout every stage of mould production. Our well-established management system ensures consistency, reliability, and accuracy, allowing us to uphold high-quality standards while keeping delivery times competitive. Our team understands the importance of timely delivery in your production schedule, and we strive to meet agreed deadlines without compromising the mould’s quality.

Additionally, our pricing is structured to provide competitive value without sacrificing craftsmanship or material standards. We aim to offer solutions that are cost-effective while maintaining excellent performance characteristics.

After-Sales Support

Our commitment to customers extends beyond the delivery of the mould. Experienced engineers are available to provide comprehensive technical support for any issues that may arise during the mould’s operation. This includes troubleshooting, maintenance guidance, and suggestions for optimisation, ensuring that your production process remains smooth and efficient over time.

Advantages of Choosing Our Foldable Chair Mould

High manufacturing efficiency is enabled by advanced equipment and automated processes

Short turnaround times to meet your project deadlines

Competitive pricing balanced with quality and performance

Flexible customisation options based on your design inputs

Strong emphasis on quality control and product consistency

Complete service from initial concept through prototyping to final mould delivery

Dedicated technical support and after-sales service

Customer Collaboration

We value close collaboration with our clients and encourage you to share your specific requirements or designs. Our team is ready to work with you to produce a foldable chair mould that meets your exact needs, whether for small-batch production or large-scale manufacturing. We support OEM projects and welcome custom design proposals, ensuring that your product vision is fully realised.

In summary, our foldable chair mould manufacturing service offers a comprehensive, professional, and reliable solution. Combining premium materials, state-of-the-art machinery, and experienced engineering, we deliver moulds that support efficient production, durability, and precision. Contact us with your requirements or designs to explore how we can assist you in bringing your foldable chair project to life.

English

English عربى

عربى Español

Español Français

Français