|

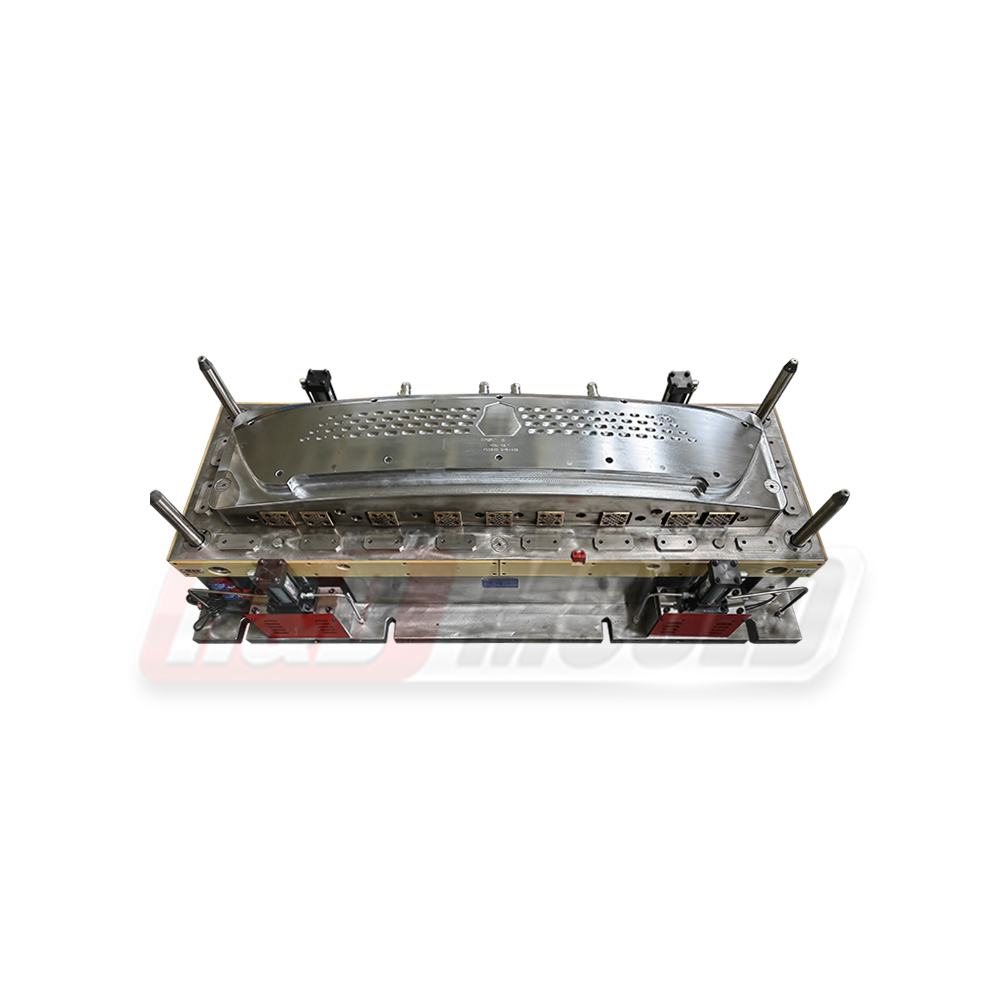

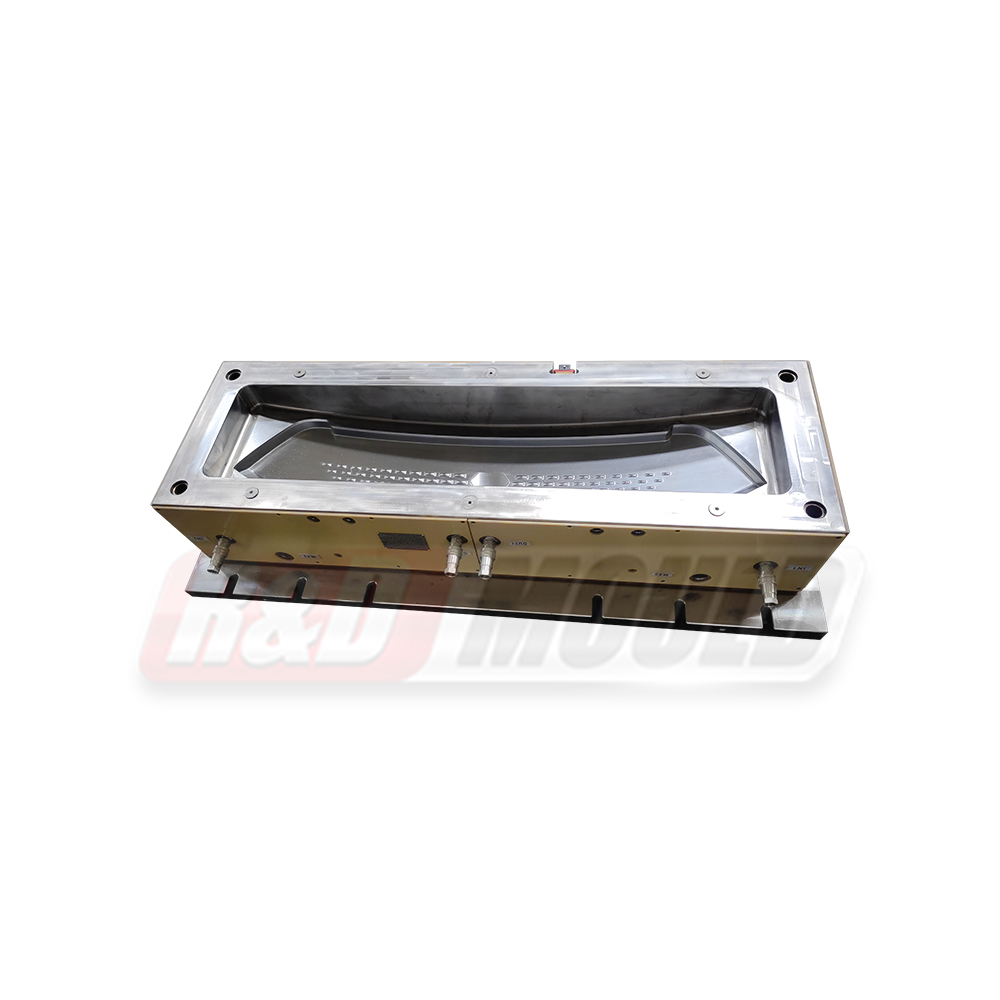

Product Name |

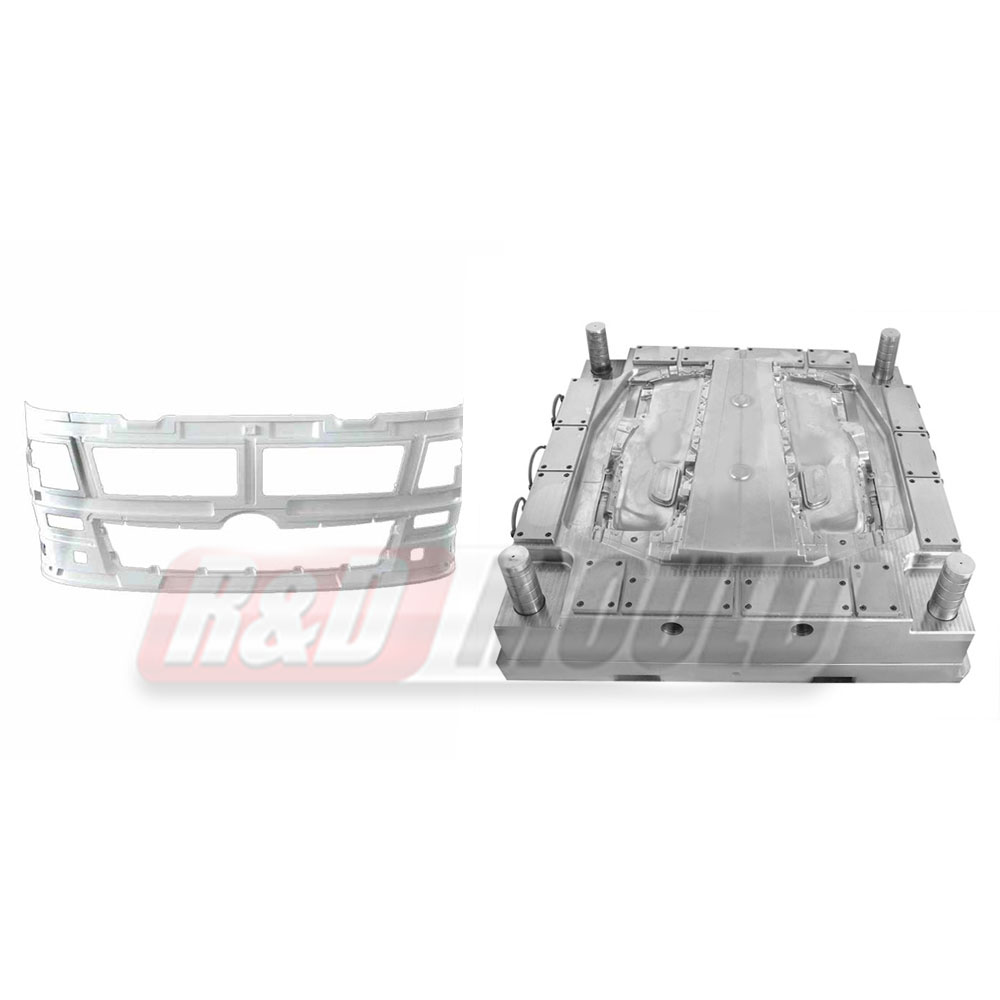

Auto Grille Mould |

|

Product Material |

SMC |

|

Mould Material |

P20 |

|

Mould Cavity |

1 |

|

Mould Life Guarantee |

300,000shots |

|

Manufacture time (day) |

55 days |

|

Demoulding |

Full automatic |

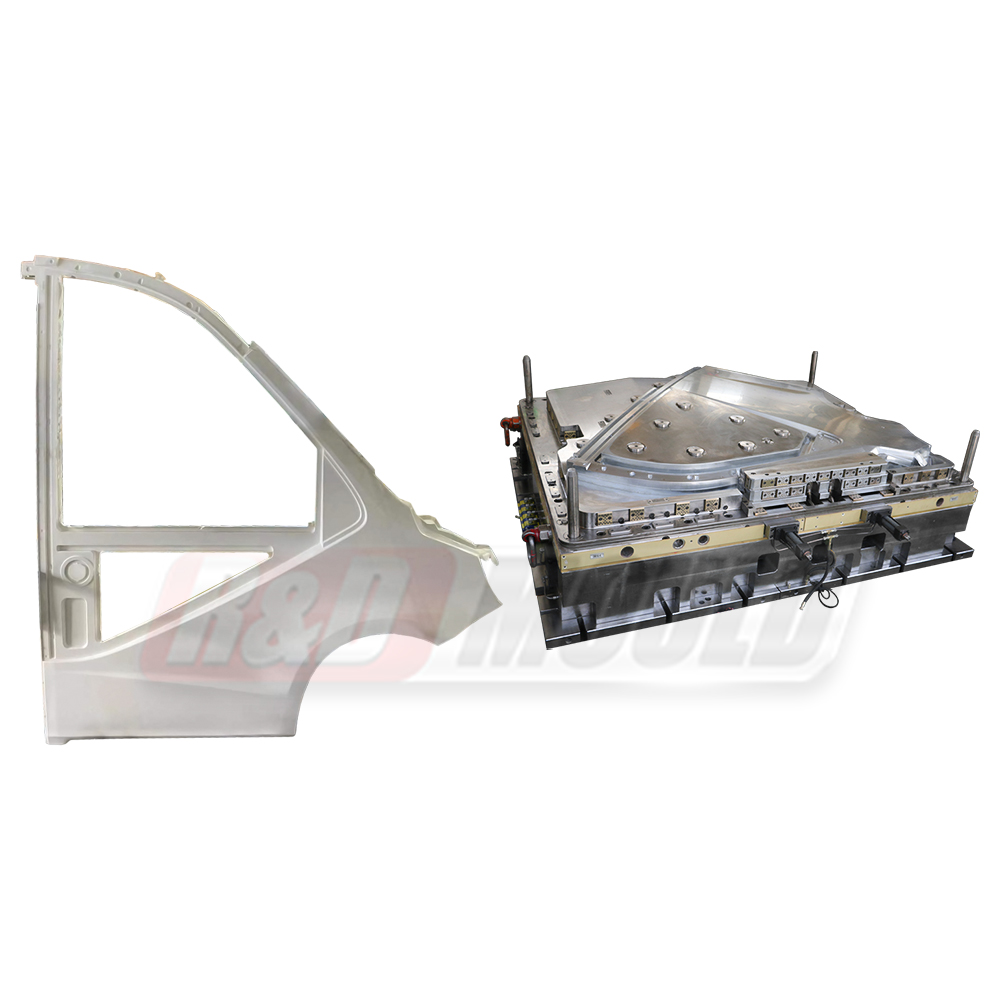

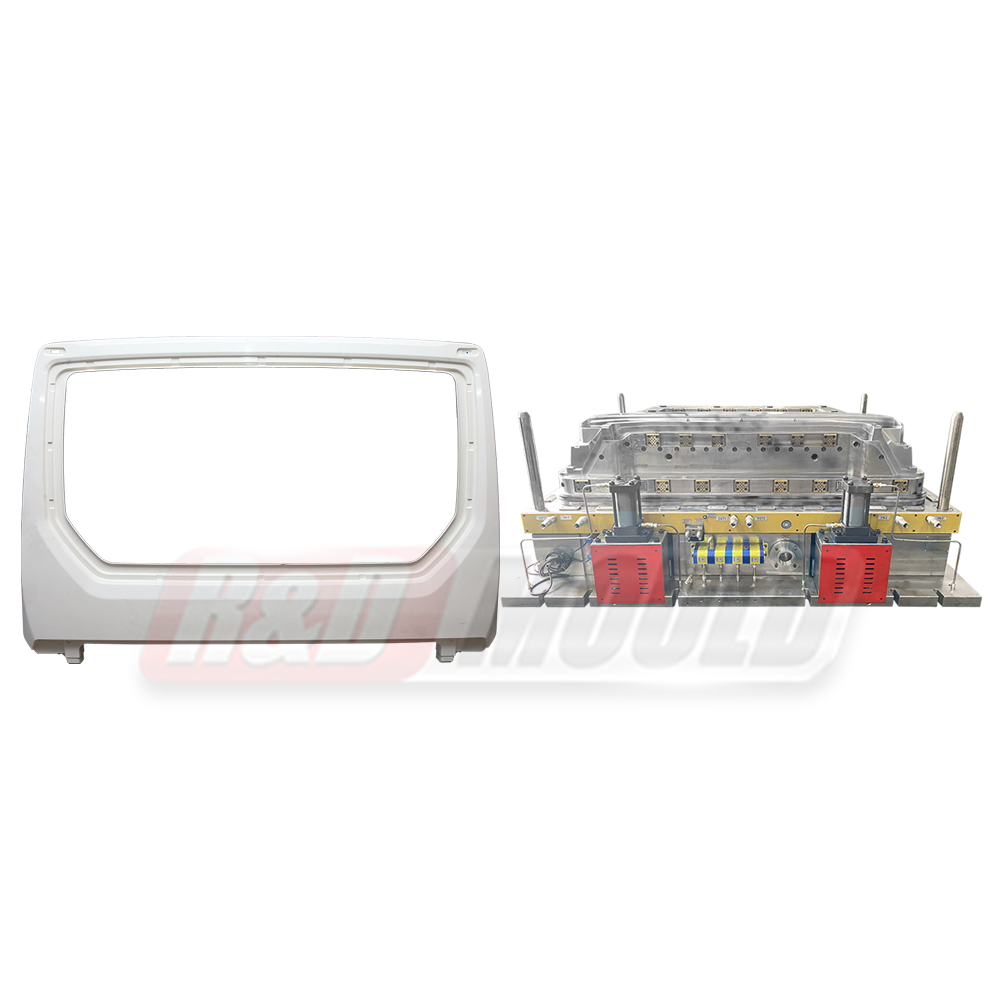

With over 15 years of unparalleled expertise, R&D Mould specializes in crafting top-quality auto grille moulds. As an esteemed company in the mould industry, we are renowned for our unwavering dedication to precision and innovation, making us the preferred choice for auto grille moulds. Our commitment to staying ahead of market demands and investing in cutting-edge technologies and modern machinery ensures our customers receive nothing but the best.

Our collaborative team of experienced mould designers and engineers works closely with clients to provide tailored solutions that meet their unique requirements. We take immense pride in the exceptional strength and durability of our moulds, meticulously designed to withstand rigorous production processes and consistently deliver outstanding, high-quality results.

The key advantages we provide are as follows:

1. Utilization of comprehensive processing equipment, guaranteeing efficiency and accuracy throughout the mould manufacturing process.

2. A team of skilled and experienced mould designers and engineers, offering a wealth of industry expertise and creativity.

3. Moulds engineered with exceptional strength and durability, ensuring longevity and cost-effectiveness for our customers.

4. Implementation of optimal cooling mechanisms to enhance productivity and minimize production cycle times.

5. Impeccable polishing techniques employed to achieve flawless finishes, adding an aesthetic touch to the final product.

6. Commitment to dedicated and reliable after-sales service, providing seamless support and addressing any concerns promptly.

7. Effective communication channels established to foster smooth collaboration, ensuring clients' needs are met throughout the project.

8. Prompt delivery of orders, enabling clients to streamline their production schedules efficiently.

9. Offering competitive pricing for all moulds, making top-notch quality accessible to businesses of all sizes

Mould Packaging Details:

1. For external packaging, we use standard export wooden cases.

2. Internally, each mould is treated with anti-corrosive oil and wrapped in plastic waterproof film.

3. Spare parts are securely packed together with the mould for shipping convenience.

At R&D Mould, customer satisfaction lies at the core of our mission. We strive to build lasting partnerships with our clients by delivering products of unparalleled quality and providing exceptional service. Our vast experience and relentless pursuit of excellence give us the confidence to consistently surpass your expectations for auto grille moulds.

English

English عربى

عربى Español

Español Français

Français