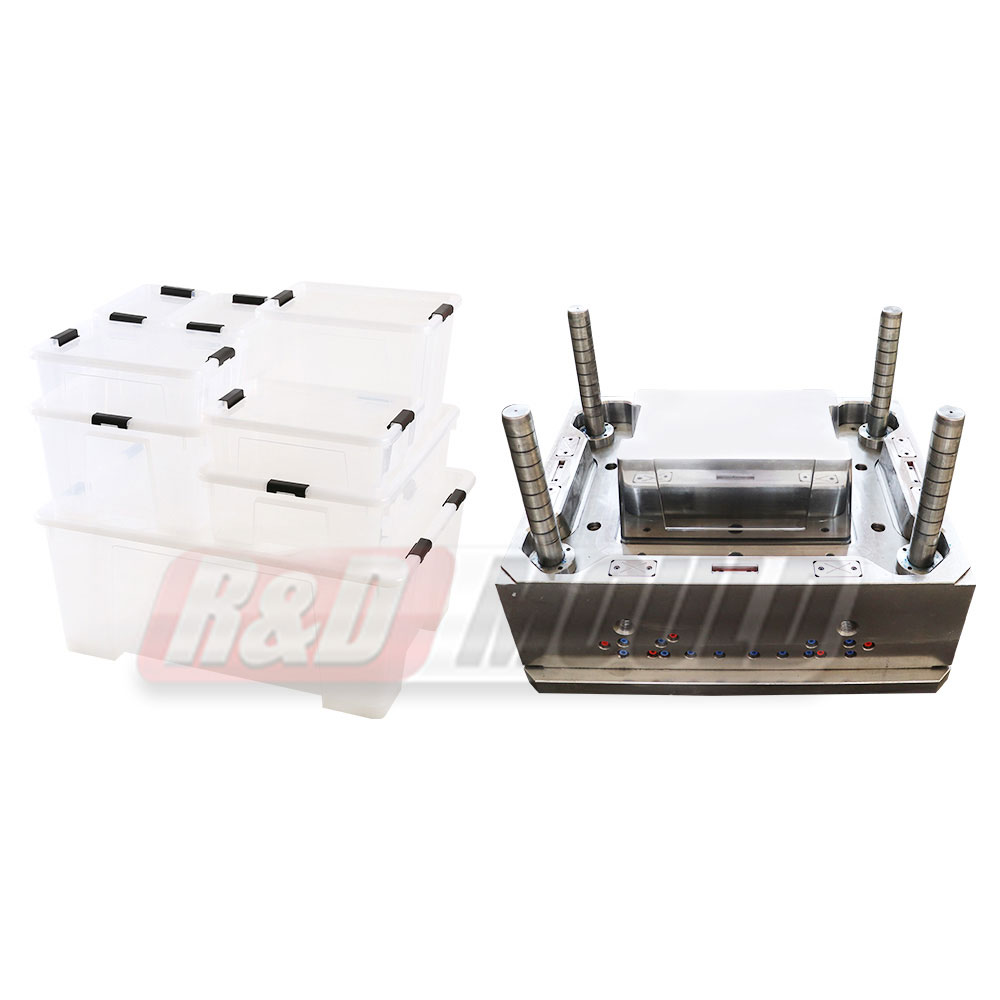

| Mold Name | 120L Storage Box Mold |

| Plastic Material | PP |

| Mold Cavity/Core Steel | P20 |

| Runner /Gate System | YUDO Hot Runner |

| Manufacture Time (Day) | 70 Days |

| Mold Life | 300,000 Shots |

| Product Size | 120L |

| Demolding | Full Automatic |

Normal storage box we make is with and without wheels, some is interchangeable insert for the wheels. This can make more options for customer. Of course, we also make some special design which customer provide us, like side open door, irregular shape...

When our design department start a project, we will make mold flow analysis first, then make design. For storage box many customers will make transparent production. So the defects in product is very fatal. Like air bubble, this is very common problem, but not so easy to adjust by machine. Therefore, when we make design, we will check carefully for this, the air venting design is so important, or the air venting will cause many problems to the production. Venting must be adequate for fast filling speed. Fast filling will show all tool defects in regards to parting lines, shut off surfaces, venting, high shear areas (gates).

R&D MOULD believes that "Details Determine Quality" and "Service Wins Over Customers". We are ready to collaborate with domestic and international customers, offer our best mould to you.

English

English عربى

عربى Español

Español Français

Français-1.jpg)

.jpg)

.jpg)